COMBINES ATTRACTIVE APPEARANCE WITH EXCELLENT MECHANICAL PROPERTIES.

| PC1142 |

PENNY VEIN METALLIC |

| CHEMISTRY |

POLYESTER TGIC B |

| REGULAR CURE TEMP |

375F / 15 MIN |

| MIN TEMP |

350F / 20 MIN |

| MAX TEMP |

400F / 10 MIN |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

H minimum |

| SPECIFIC GRAVITY |

1.40 +/-0.05 g/cm³ |

| THEORETICAL COVERAGE |

137 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

500 hours |

| BALL IMPACT |

40 in/lb |

| SDS Sheet info # |

#6B – Polyester TGIC (Group B) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

ROCKSTAR BLACK TGIC POLYESTER POWDER

HAS A MIXTURE OF MEDIUM TO LARGE GOLD FLAKE THROUGH THE FINISH. GET THE MOST BLING FOR YOUR BUCK

| CHEMISTRY |

ROCKSTAR BLACK |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.26 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Great to use as a base coat for candy colours.

| PC1177 |

SILVER VEIN METALLIC |

| CHEMISTRY |

POLYESTER TGIC C |

| REGULAR CURE TEMP |

15 Minutes@ 375°F |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.68 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6C – Polyester TGIC (Group C) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

SAFETY YELLOW has been updated to the new TGIC free version. Do not mix with older versions.

| PC1167 |

SAFETY YELLOW (TGIC FREE VERSION) |

| CHEMISTRY |

POLYESTER TGIC-FREE |

| REGULAR CURE TEMP |

356F 10-23 MIN |

| MIN TEMP |

320F 15-30 MIN |

| MAX TEMP |

400F 5-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#4 – Polyester TGIC Free |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

ZINC RICH PRIMER EPOXY

KNOWN FOR OUTSTANDING CORROSION RESISTANCE FOR STEEL PARTS ONLY

| PC1206 |

ZINC RICH PRIMER |

| CHEMISTRY |

Epoxy |

| REGULAR CURE TEMP |

10 Minutes@ 350°F |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.5 TO 2.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

2.95 +/- .05 |

| THEORETICAL COVERAGE |

NA |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

60-85 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#1 – Zinc Primer |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

ZINC RICH PRIMER EPOXY

KNOWN FOR OUTSTANDING CORROSION RESISTANCE FOR STEEL PARTS ONLY,*When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Neon Yellow powder coat. The brightest yellow powder coat that we sell. The powder lays down super smooth and flows out to a high gloss finish. LIMITED UV STABILITY

| PC1182 |

NEON YELLOW |

| CHEMISTRY |

POLYESTER TGIC |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

500 hours |

| BALL IMPACT |

20 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| LIMITED UV STABILITY. May fade with repeated outdoor exposure, Even with a clear coat you still may see fading *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. |

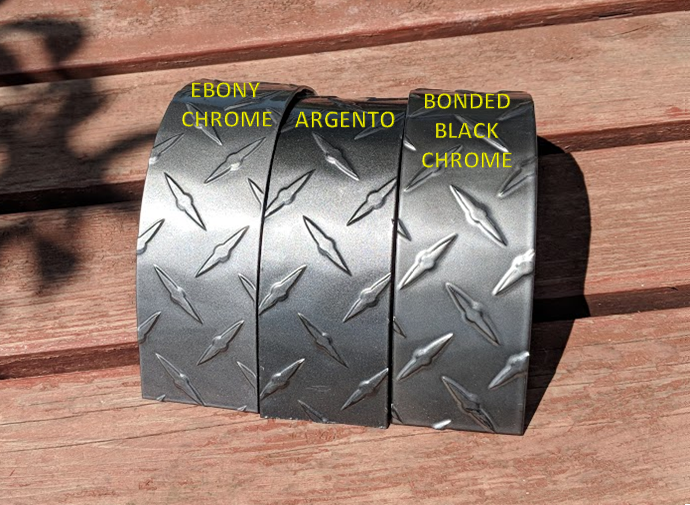

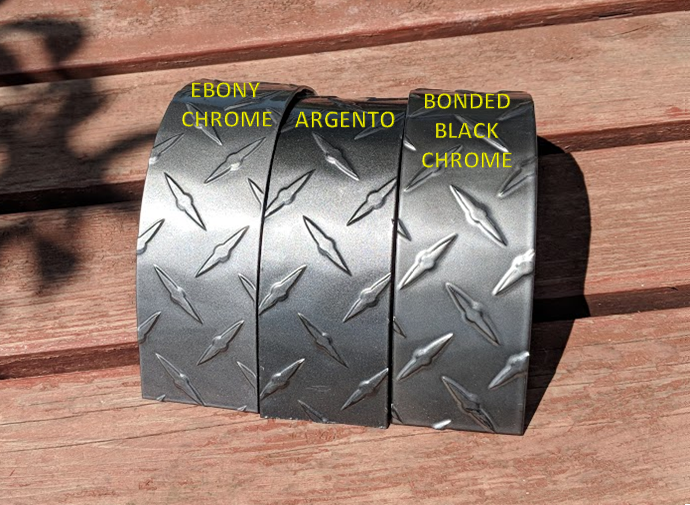

EBONY CHROME

THIS PRODUCT IS ANOTHER ADDITION TO OUR BLACK/SMOKE CHROMES

| PC1059 |

EBONY CHROME |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

400F/10 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2-H |

| SPECIFIC GRAVITY |

1.24 +/- .05 |

| THEORETICAL COVERAGE |

155ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Check out our Wheel Silver for a close match to this colour.

| PC1117 |

MIRROR SILVER SPARKLE |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

BLACK WRINKLE POLYESTER POWDER

A MUST FOR ANY COATER THAT HAS HARLEY DAVIDSON CUSTOMERS. SPECIALLY FORMULATED TO MATCH S&S MOTORS THIS WEATHER RESISTANT WRINKLE IS PERFECT FOR ACCENTING ANY HARLEY DAVIDSON.

| PC1022 |

BLACK WRINKLE |

| CHEMISTRY |

Polyester TGIC Free |

| REGULAR CURE TEMP |

375F/15 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.2-2.8 Mils |

| PENCIL HARDNESS |

HB |

| SPECIFIC GRAVITY |

1.31 ± 0.05 |

| THEORETICAL COVERAGE |

58.8 SQ. |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

30-39% |

| SALT SPRAY |

1,000 hrs |

| BALL IMPACT |

120 / 40 in/lbs |

| SDS Sheet info # |

#7 – Black wrinkle |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. USE ZINC RICH PRIMER OVER STEEL PARTS FOR EXTERIOR APPLICATIONS |

SCREAMIN EAGLE BLACK CRINKLE

| PC1173 |

SCREAMIN EAGLE BLACK CRINKLE |

| CHEMISTRY |

POLYURETHANE GROUP B |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.5-4.0 mils |

| PENCIL HARDNESS |

H minimum |

| SPECIFIC GRAVITY |

1.41 +/-0.05 g/cm³ |

| THEORETICAL COVERAGE |

136.38 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

0-10 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

140 in/lb |

| SDS Sheet info # |

#5B – Polyurethanes (Group B) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |