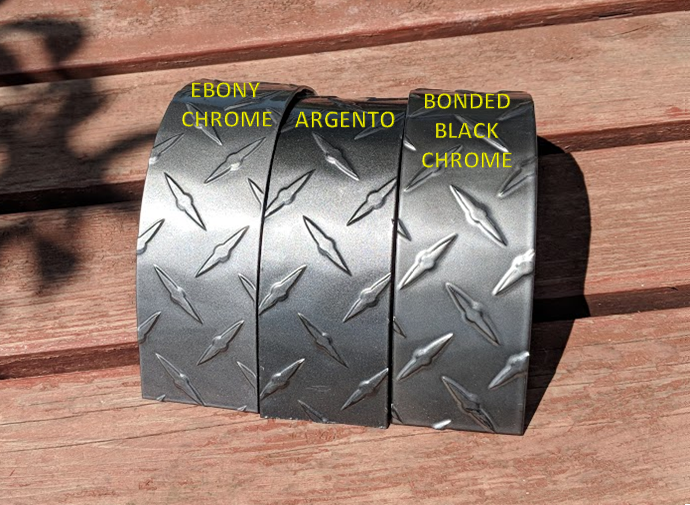

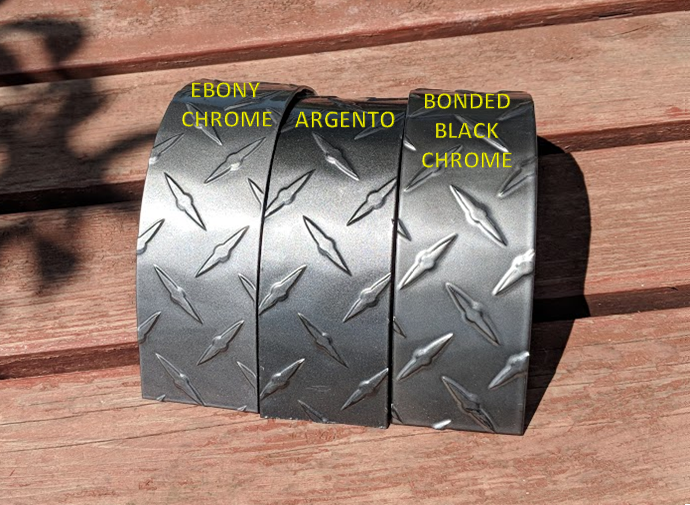

EBONY CHROME

THIS PRODUCT IS ANOTHER ADDITION TO OUR BLACK/SMOKE CHROMES

| PC1059 |

EBONY CHROME |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

400F/10 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2-H |

| SPECIFIC GRAVITY |

1.24 +/- .05 |

| THEORETICAL COVERAGE |

155ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Check out our Wheel Silver for a close match to this colour.

| PC1117 |

MIRROR SILVER SPARKLE |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

BLACK WRINKLE POLYESTER POWDER

A MUST FOR ANY COATER THAT HAS HARLEY DAVIDSON CUSTOMERS. SPECIALLY FORMULATED TO MATCH S&S MOTORS THIS WEATHER RESISTANT WRINKLE IS PERFECT FOR ACCENTING ANY HARLEY DAVIDSON.

| PC1022 |

BLACK WRINKLE |

| CHEMISTRY |

Polyester TGIC Free |

| REGULAR CURE TEMP |

375F/15 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.2-2.8 Mils |

| PENCIL HARDNESS |

HB |

| SPECIFIC GRAVITY |

1.31 ± 0.05 |

| THEORETICAL COVERAGE |

58.8 SQ. |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

30-39% |

| SALT SPRAY |

1,000 hrs |

| BALL IMPACT |

120 / 40 in/lbs |

| SDS Sheet info # |

#7 – Black wrinkle |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. USE ZINC RICH PRIMER OVER STEEL PARTS FOR EXTERIOR APPLICATIONS |

SCREAMIN EAGLE BLACK CRINKLE

| PC1173 |

SCREAMIN EAGLE BLACK CRINKLE |

| CHEMISTRY |

POLYURETHANE GROUP B |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.5-4.0 mils |

| PENCIL HARDNESS |

H minimum |

| SPECIFIC GRAVITY |

1.41 +/-0.05 g/cm³ |

| THEORETICAL COVERAGE |

136.38 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

0-10 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

140 in/lb |

| SDS Sheet info # |

#5B – Polyurethanes (Group B) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

AQUA SPLASH BLUE BURST POLYESTER TGIC POWDER

THIS PRODUCT LOOKS DARK IN THE SHADE AND THEN REALLY POPS IN THE SUNLIGHT.

• CURE TIME = 340F/10 MIN @ PMT (PART METAL TEMPERATURE) • RECOMMENDED MIL THICKNESS = 2.0 – 3.0 MILS • GLOSS LEVEL = 90+% • SPECIFIC GRAVITY = 1.34 • SALT SPRAY RESULTS = 1,000+ HOURS

*CLEAR COAT RECOMMENDED FOR EXTERIOR APPLICATIONS AND A BETTER GLASS LOOKING FINISH

FORMULATION CHANGE **As of SEPT 8th, 2021, this colour has changed, to the Axalta HHA TGIC Free formulation. Do not mix this powder with previous batches.

AXALTA RAL 9005

| RAL9005A |

RAL 9005 JET BLACK (NEW TGIC FREE VERSION, do not mix with old version) |

| CHEMISTRY |

HAA POLYESTER TGIC FREE |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.36 ± 0.05 |

| THEORETICAL COVERAGE |

141 ft /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-90+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

140 in/lbs |

| SDS Sheet info # |

#15 HAA POLYESTER TGIC FREE |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| HAA, TGIC FREE, RAL COLOUR, DO NOT MIX WITH PREVIOUS TGIC VERSION, ENSURE GOOD GUN CLEANING BETWEEN COLOUR CHANGES TO PREVENT CROSS CONTAMINATION. WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

FORMULATION CHANGE **As of Aug 31st 2021, this colour has changed, to the Axalta HHA TGIC Free formulation. Do not mix this powder with previous batches.

AXALTA RAL 9010

| ral9010a |

RAL 9010 PURE CHARLET WHITE (NEW TGIC FREE VERSION, do not mix with old version) |

| CHEMISTRY |

HAA POLYESTER TGIC FREE |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.64 ± 0.05 |

| THEORETICAL COVERAGE |

117 ft /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-90+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lbs |

| SDS Sheet info # |

#15 HAA POLYESTER TGIC FREE |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| HAA, TGIC FREE, RAL COLOUR, DO NOT MIX WITH PREVIOUS TGIC VERSION, ENSURE GOOD GUN CLEANING BETWEEN COLOUR CHANGES TO PREVENT CROSS CONTAMINATION. WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

FORMULATION CHANGE **As of FEB28th 2022, this colour has changed, to the Axalta HHA TGIC Free formulation. Do not mix this powder with previous batches.

|

ral9016a |

RAL 9016 TRAFFIC WHITE (NEW TGIC FREE VERSION, do not mix with old version) |

| CHEMISTRY |

HAA POLYESTER TGIC FREE |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.76 ± 0.05 |

| THEORETICAL COVERAGE |

109 ft /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-90+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lbs |

| SDS Sheet info # |

#15 HAA POLYESTER TGIC FREE |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| HAA, TGIC FREE, RAL COLOUR, DO NOT MIX WITH PREVIOUS TGIC VERSION, ENSURE GOOD GUN CLEANING BETWEEN COLOUR CHANGES TO PREVENT CROSS CONTAMINATION. WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

AGRICULTURAL Yellow FROM AXALTA IS MADE TO MATCH THE JOHN DEERE Yellow AXALTA PART # PFG678S9 Name: Agricultural Yellow

| PC1096a |

JD AGRICULTURAL Yellow |

| CHEMISTRY |

POLYESTER TGIC Axalta |

| REGULAR CURE TEMP |

400F/10 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.31+/-0.05 |

| THEORETICAL COVERAGE |

147 ft2/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

90+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

60 in/lb |

| SDS Sheet info # |

#6D – Polyester TGIC (AXALTA) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |