AIR CURE TUNGSTEN CERAKOTE

Cure Schedule:

Tack free at 40 minutes

Dry after 24-hours

100% cure after 5days

can withstand 1200f with out discoloring so is ideal for exhaust

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

NEW BONDED DORMANT BLUE

*****WILL COME OUT SILVER WITHOUT A CLEAR COAT******

| PC1127 |

NEW BONDED DORMANT BLUE |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

340F/10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2 – 3.0+ mil |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.27 +/- 0.05 |

| THEORETICAL COVERAGE |

151 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

100 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Dormant Colours need a clear coat for the full colour to come through. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

WILL COME OUT SILVER WITHOUT A CLEAR COAT

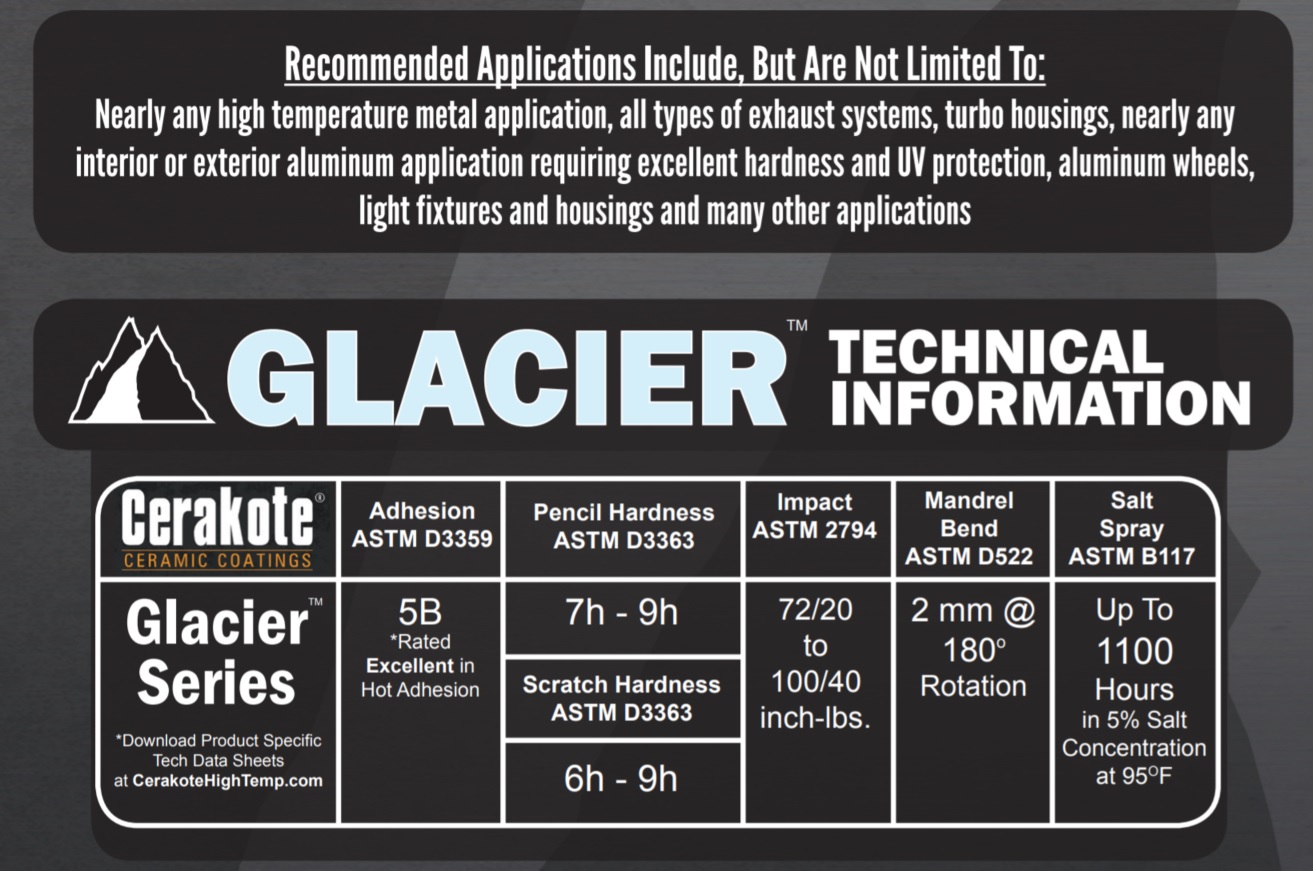

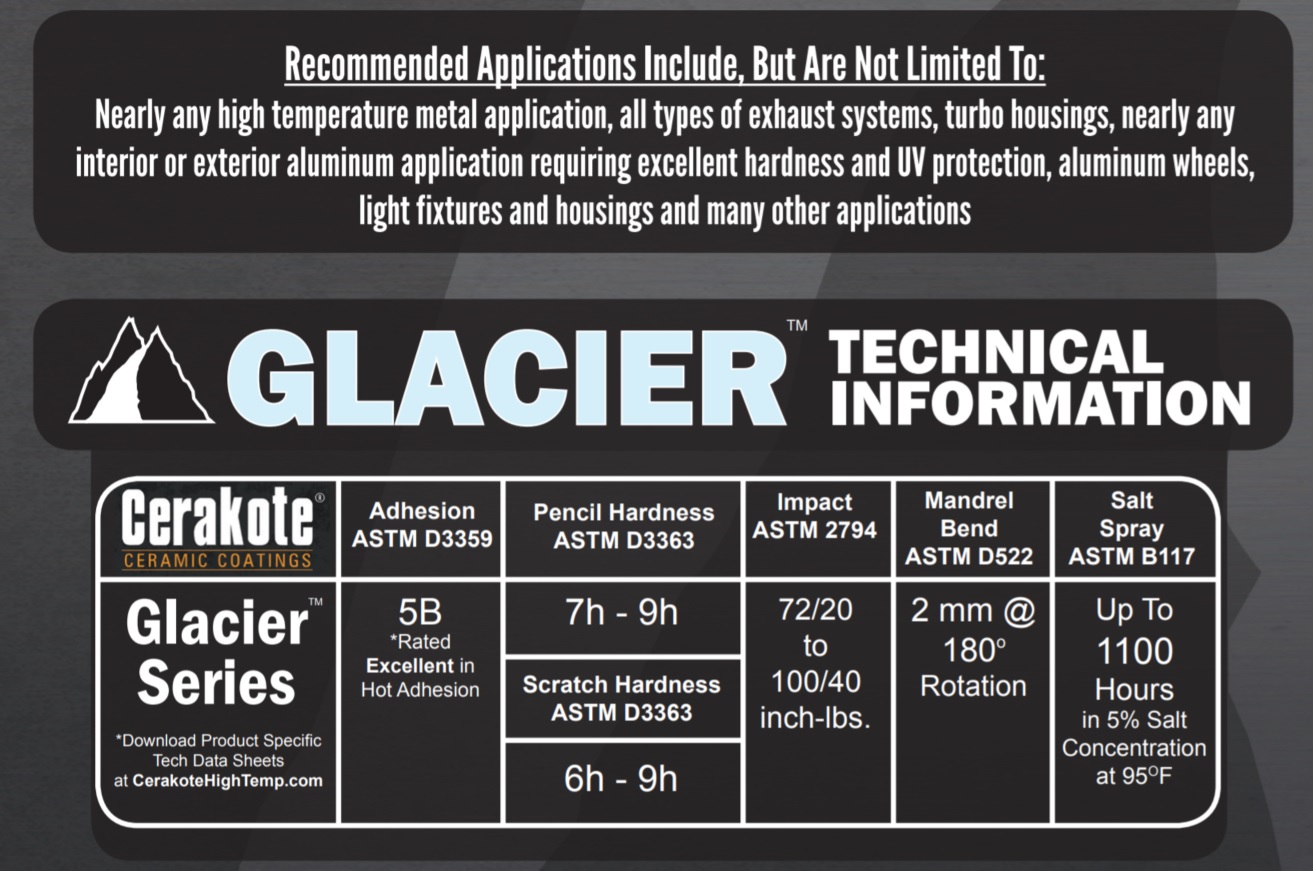

AIR CURE CERAKOTE GLACIER BLACK 1800F

Cure Schedule (Ambient Temperature): Dry to touch at 4 hours Ready for use at 12 hours Full cure at 72 hours

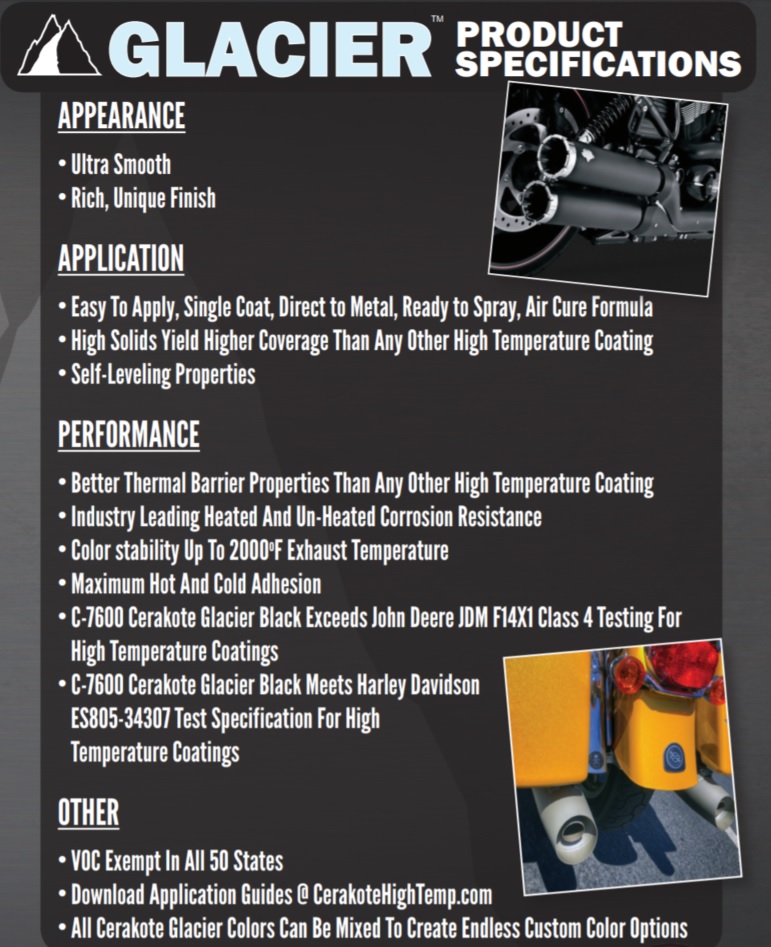

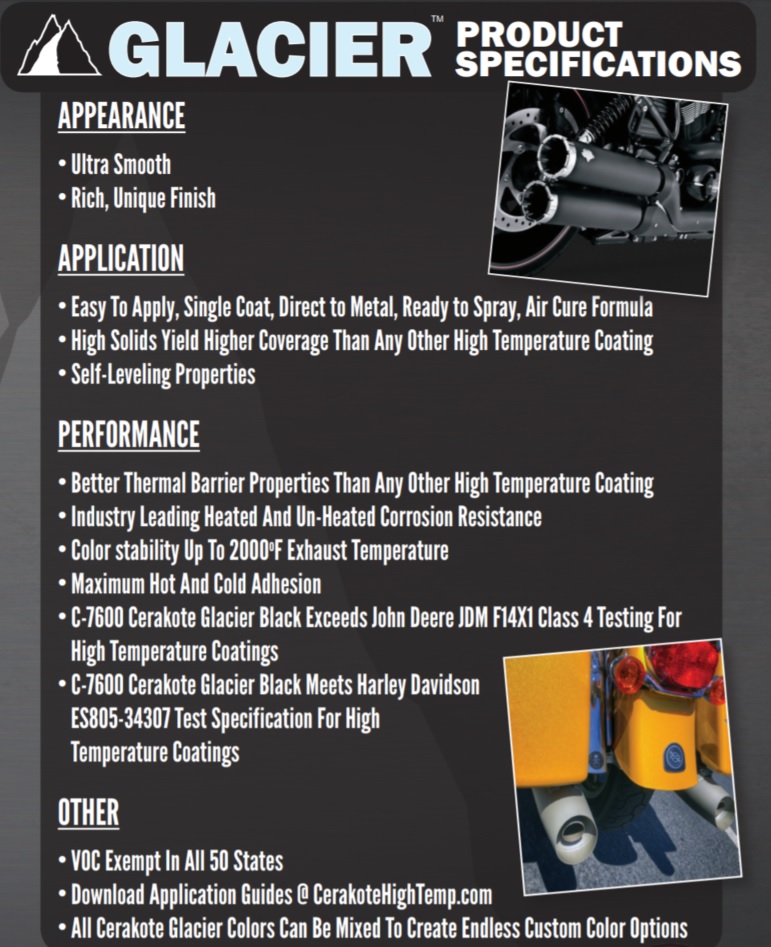

Unsurpassed. No other word can adequetely describe Cerakote C-7600 Glacier Black coating. Formulated to withstand temperatures of over 2,000 degrees Fahrenheit and thermal shock from those temperatures directly into water with no adverse effects, C-7600 retains its deep black, sleek satin finish in the most extreme environments. C-Series coatings are a line of air cured, ready to spray ceramic coatings.Appearance * Ultra smooth* Deep, rich black finishApplication* Easy to apply, Single coat, Air cure formula * 85% solids yields higher coverage than any other high temp coating* Self-leveling propertiesOther* VOC Exempt in all 50 statesPerformance*Better thermal barrier properties than any other high temperature coating* Industry leading heated and un-heated corrosion resistance* No discoloration, even past 2000

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

12 MM GEMMA POWDER COATING SYSTEM HOSE.

*** SOLD BY THE FOOT ***

If you’re looking for a replacement for real chrome, this is not it. Chrome powders look good but nothing close to real chrome. Works great as a base for candy colours. Can be used on its own but will need to be clear coated. The clear coat will dull the look down, the product will not hold up without a clear. Best to use the Acrylic clear for the least amount of Dulling. The Mirror clear is also another option.

| PC1028 |

BONDED BRIGHT CHROME |

| CHEMISTRY |

POLYURETHANE GROUP A |

| REGULAR CURE TEMP |

400F/15 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.8-2.2 mils |

| PENCIL HARDNESS |

H |

| SPECIFIC GRAVITY |

1.2 +/-0.05 g/cm³ |

| THEORETICAL COVERAGE |

161.59 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

125+ |

| SALT SPRAY |

2000 |

| BALL IMPACT |

100 in/lb |

| SDS Sheet info # |

#5A – Polyurethanes (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Needed, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. Chrome powder will tarnish and scratch easy if not clear coated. Cure the base coat around 90% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. Chrome powder can also be top coated with candy colours. |

RAL 7047

~POLYESTER TGIC

~ CURE SCHEDULE 375F/10 MIN. @ P.M.T.

~ GLOSS @ 60 DEGREE METER-85%+/-3%

~ RECOMMENDED MIL THICKNESS – 2.5-3.5 MILS

~ SPECIFIC GRAVITY – 1.65

~ THEORETICAL COVERAGE @ R.M.T. – 117 FT2

~ SALT SPRAY RESULTS – 1,000 HOURS +

32-ply.

These buffs are sewn with two rows to slightly stiffen the buff.

This improves the speed of the final coloring operation, giving you performance somewhere between a spiral sewn and a loose wheel.

Sisal is a slender, hard, cellular strand of fiber that has demonstrated its great strength and tough resiliency in the form of binder twine, cord & rope for many years. These qualities, along with its natural abrading and grease absorbing characteristics, provide an ideal buffing wheel fabric.

Sisal buffing wheels will provide both polishing and cutting action. They will remove stretcher strains, orange peel, polishing wheel grit lines, light die marks, etc.

To effect a fast cut, use a Sisal Wheel with the Black Emery compound.

| PC1183 |

SPARKLE BOMBER ORANGE DORMANT |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

3.5-4.5 mils |

| PENCIL HARDNESS |

2-H |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm10 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Dormant Colours need a clear coat for the full colour to come through. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

USING A CLEAR COAT IS RECOMENDED TO BRING OUT DESIRED COLOR, YOU WILL NOT GET THE COLOR AND DEPTH UNLESS YOU USE A CLEAR COAT.