Experienced users know that moisture cannot be present when painting, and even though your spraying system may have moisture traps and filters, condensation may occur in the hose downstream and ruin your paint job.

Dry-Air Spray Gun Filter

This great filter will absorb up to one (1) fluid ounce of moisture and insure a perfectly dry system from start to finish every time. It absorbs oil aerosols, condensed moisture, and contaminants as small as 0.01 microns. It attaches directly to the air inlet of your spray gun and, as air passes between the filter’s compressed layers, particles and moisture are trapped.

This incredible filtration is accomplished at a true 30 CFM to the spray gun, with minimal pressure drop at the optimum flow rate.

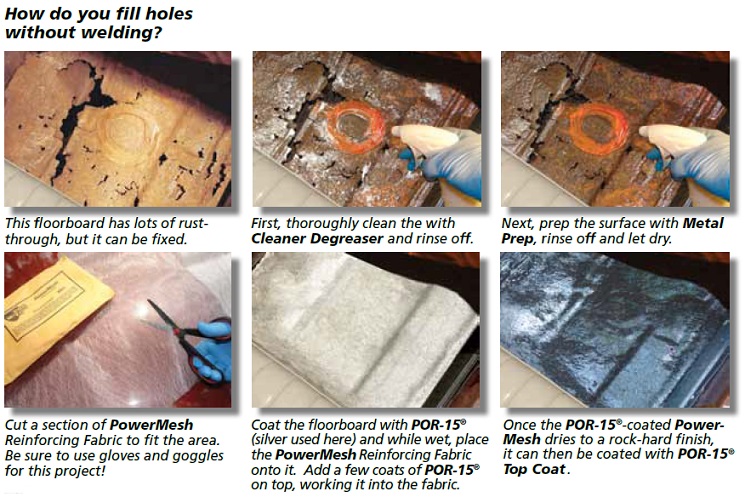

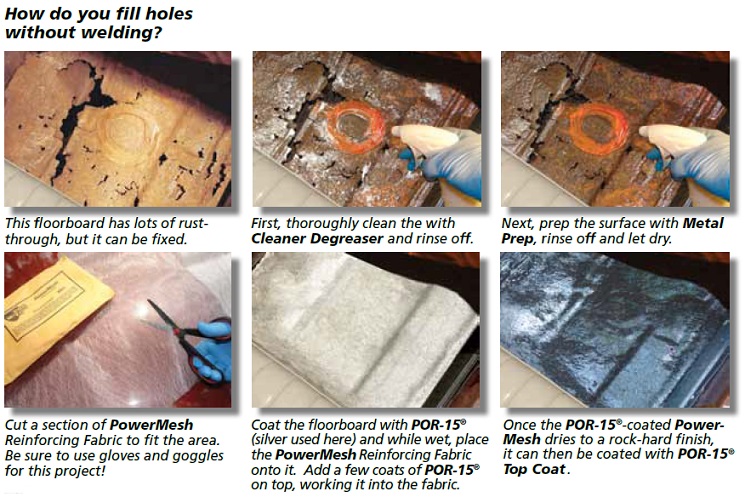

POWER MESH (1 SQ, YD)

A special fiberglass reinforcing fabric that can be used with POR15 Rust Preventive paint to bridge gaps and repair holes in sheet metal.

Handling Instructions: Do not handle fabric with bare hands.

Because it is a special type of fiberglass cloth, the fibers may pierce your skin and you will experience discomfort. Wear a pair of gloves (or other protection) whenever you handle this cloth. As you cut the cloth, some fibers may fly into the air, so be sure to wear the mask provided while cutting. Please note that there is one large piece of cloth in this envelope.

Cerakote Ceramic Clears are the strongest clear coats on the market. Cerakote Matte Ceramic Clear MC-161 leads the industry in hardness, chemical resistance, wear performance and UV stability. As a matte, air cured, ceramic clear coating, MC-161 can be used as a top coat over several materials such as metals, paints, composites, plastics, hydrographics, PVD and more. Click here to be sure you’re using the best Cerakote Clear for your project.

- Color stability to 300°F

- Ease of application

- VOC compliant and can be sprayed in all 50 states

- Tack free at 45-60 minutes

- Dry after 24-hours (full cure after 5 days)

- This coating excels in outdoor applications

- 100% Inorganic Formulation is completely UV stable. Will not yellow or haze.

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

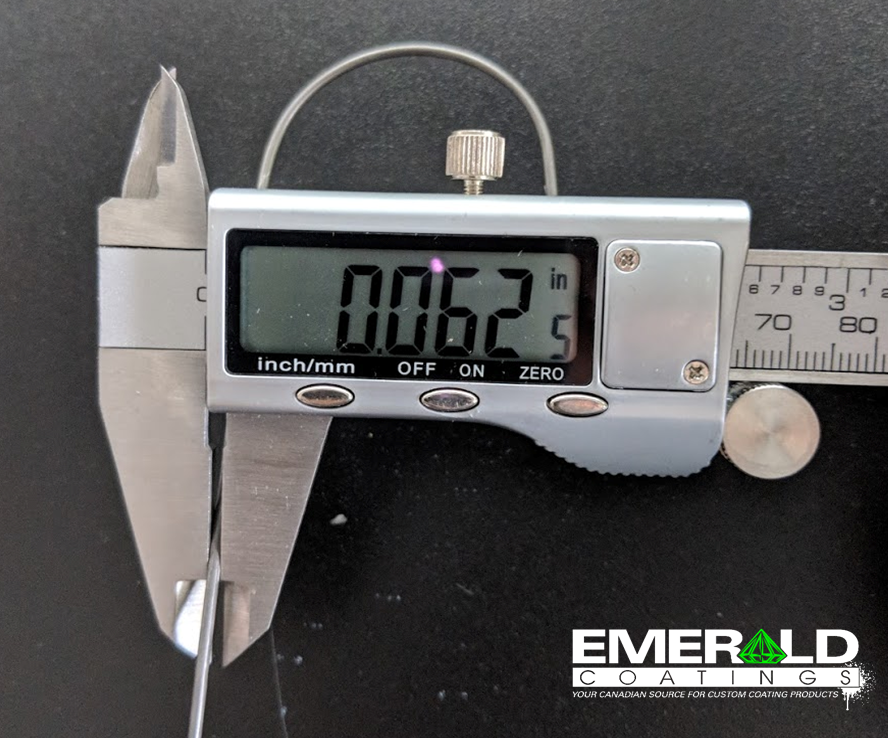

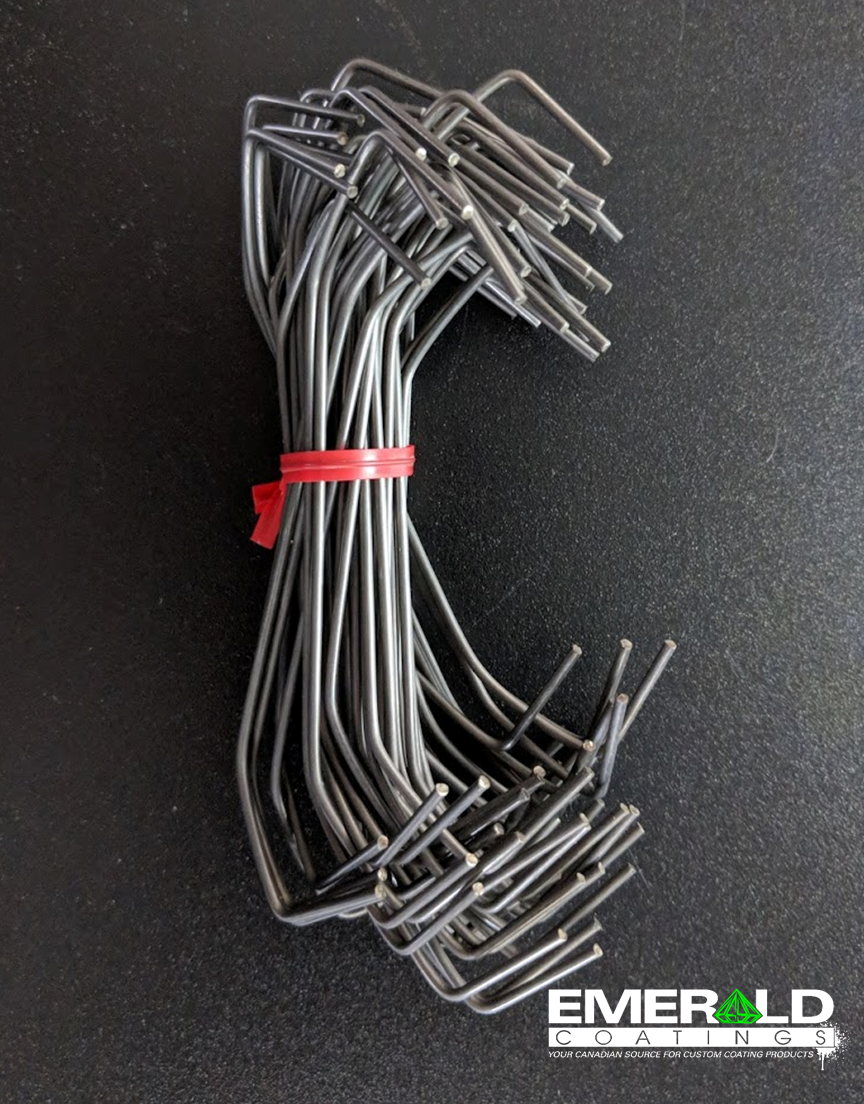

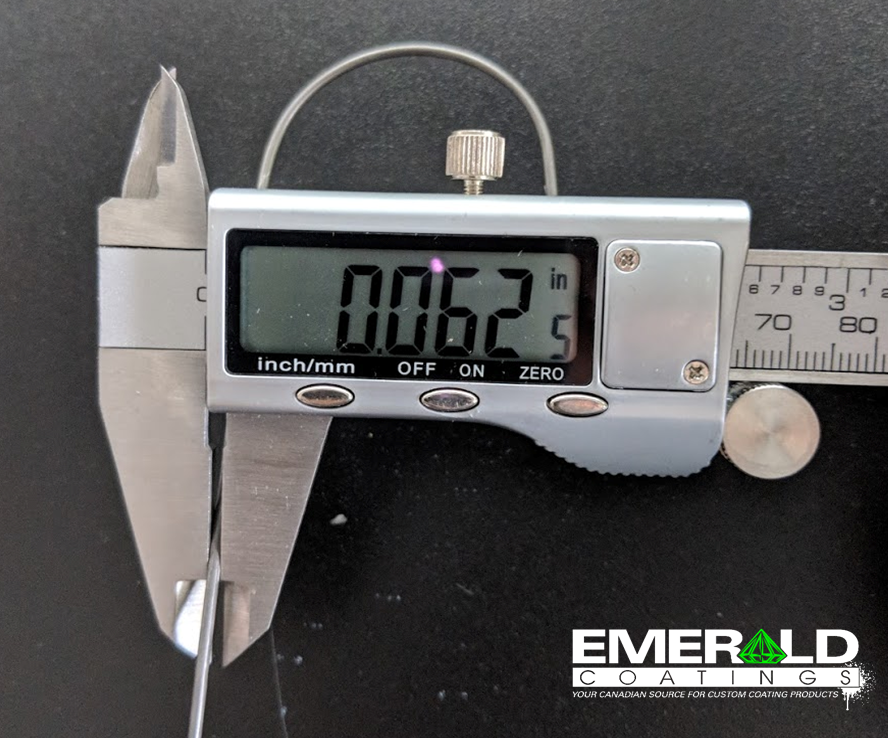

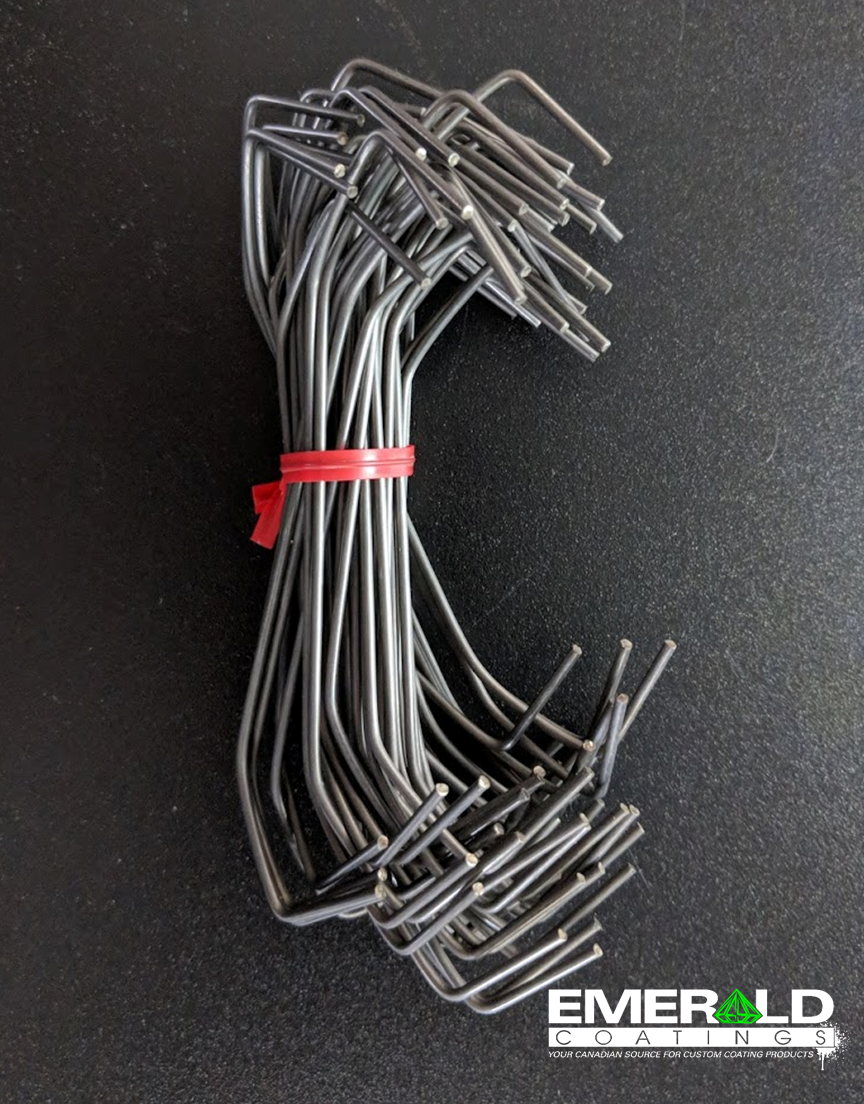

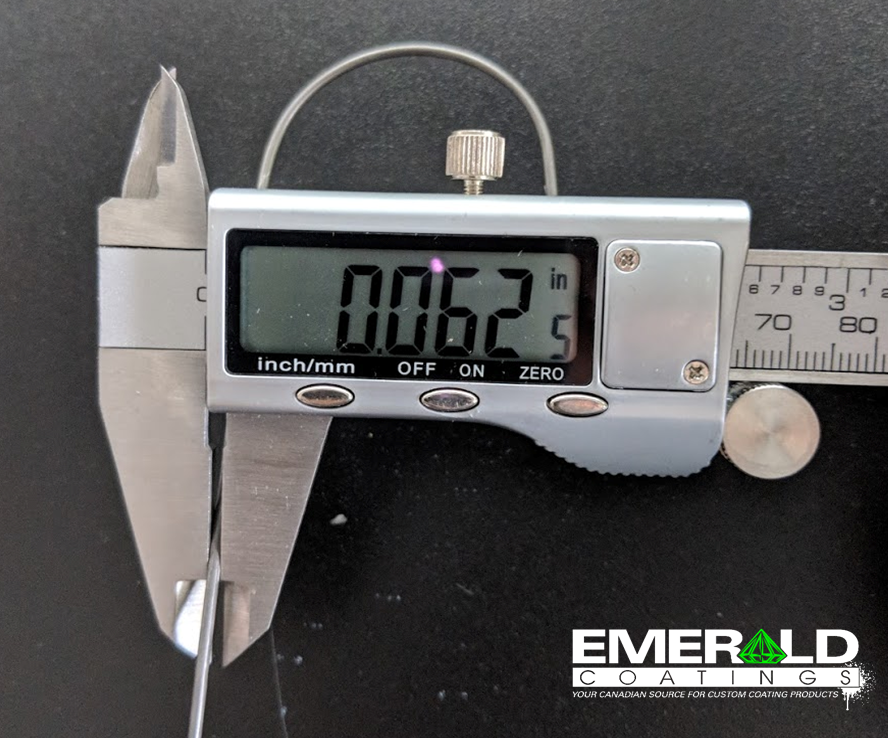

.062″ X 3″ LONG V HOOK ( 50 COUNT )

Weight capacity is approximately 12 LBS.

.060″ X 4″ LONG C HOOK (50 COUNT)

Weight capacity is approximately 8 LBS.

.060″ X 4″ LONG V HOOK ( 50 Count)

Weight capacity is approximately 8 LBS.

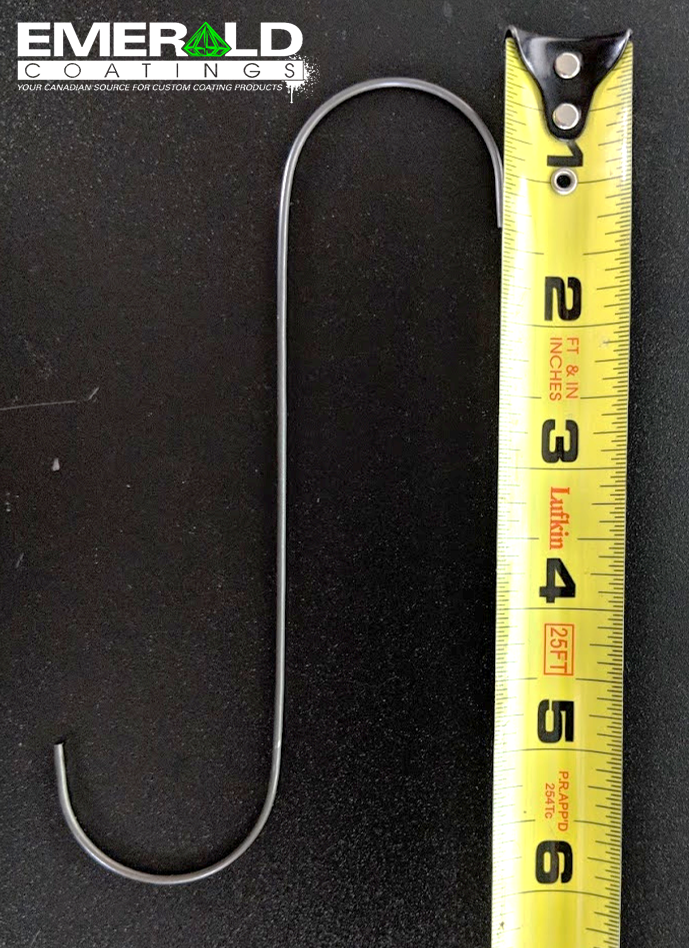

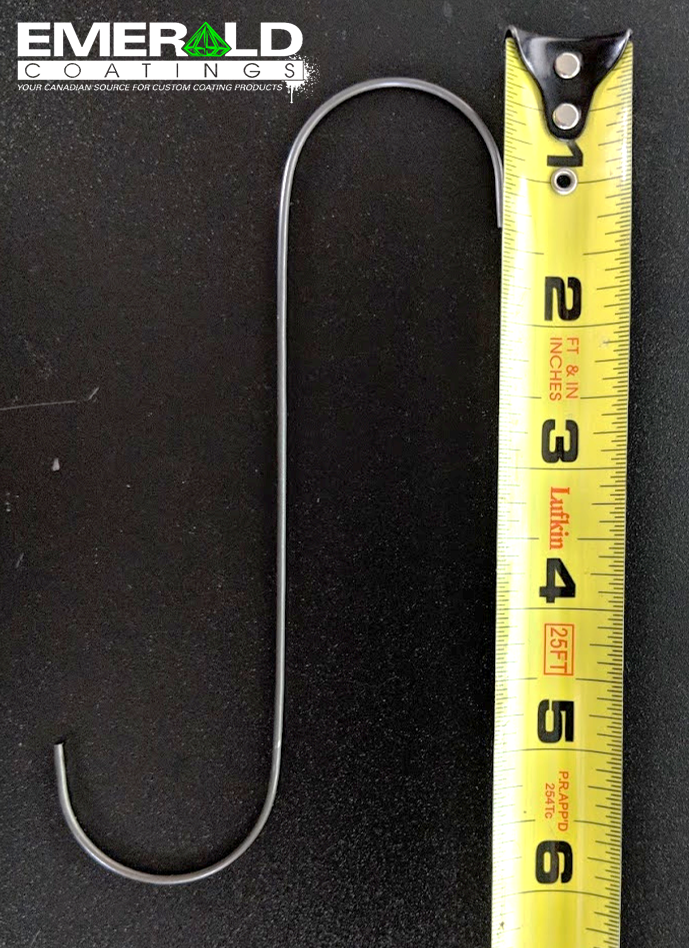

068″ X 6″ LONG S HOOK ( 50 COUNT )

Weight capacity is approximately 12 LBS.

.080″ X 10″ LONG V HOOK ( 50 COUNT )

Weight capacity is approximately 15 LBS.

Heavy-Duty Swivel “V” Hook for Coating Applications

Transform your finishing process with our Heavy-Duty Swivel Hook. This hook hangs large parts during coating and is made from 100% solid steel. It holds up to 300 lbs (136 kg), making it ideal for heavy-duty jobs. Easily rotate parts while spraying to ensure full coverage.

Key Features:

- High-Temperature Resistant: Withstands heat up to 600°F. You can leave the hook in the oven during curing.

- Smooth 360˚ Rotation: The strong double ball-bearing construction allows easy rotation. Get full access to every angle of your part. It’s perfect for powder coating, painting, media blasting, and ceramic coating.

- Durable and Reliable: The sealed internal mechanism ensures durability and consistent performance, even under heavy loads.

- Versatile Applications: Hang wheels, motorcycle frames, and bulky items with ease. The design lets you turn parts easily to paint all sides.

- Dimensions: The bottom V loop measures 1.875″ in diameter and 1.745″ high, with a total hook height of 5″.

Hang parts for powder coating or painting with our swivel hook and enjoy the convenience it brings to your workflow!

AIR CURE BLACK VELVET CERAKOTE 1800F

is a very popular finish on motorcycle pipes and automotive headers as well as many other high temperature industrial uses. Black Velvet is a smooth deep black finish with a velvety look. Cerakote C- Series Ceramic Coatings will perform at temperatures up to 1800F and set the industry standard in high temperature coatings. C-Series coatings are a line of air cured, ready to spray ceramic coatings

Cure Schedule:

Tack free at 40 minutes

Dry after 24-hours

100% cure after 5days

can withstand 1200f with out discoloring so is ideal for exhaust

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

Jet Black is a great option for those seeking a true flat black. Also check out our most popular high temp black, C-7600 Cerakote Glacier Black which has a smooth black finish. CerakoteTM C- Series Ceramic Coatings will perform at temperatures up to 1200F and set the industry standard in high temperature coatings. C-Series coatings are a line of air cured, ready to spray ceramic coatings.

Click the resources button for product application guides, technical data sheets and MSDS information.

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

SPARKLE GRANNY SMITH DORMANT TGIC , POLYESTER

| PC1185 |

SPARKLE GRANNY SMITH DORMANT |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE SCHEDULE |

375F / 20 MIN |

| MIN RANGE |

356F / 25 MIN |

| MAX RANGE |

400F / 15 MIN |

| RECOMMENDED THICKNESS |

3.5-4.5 mils |

| PENCIL HARDNESS |

2-H |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm10 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Dormant Colours need a clear coat for the full colour to come through. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

USING A CLEAR COAT IS RECOMENDED TO BRING OUT DESIRED COLOR, YOU WILL NOT GET THE COLOR AND DEPTH UNLESS YOU USE A CLEAR COAT.

Amazing bright Orange with a stunning gold pearl in the finish.

| MC1075 |

SUN BLAZE ORANGE |

| CHEMISTRY |

SD POLYESTER TGIC |

| REGULAR CURE SCHEDULE |

375F/10 MIN |

| MIN RANGE |

350F/15 MIN |

| MAX RANGE |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.5 TO 4.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.40 +/- .05 |

| THEORETICAL COVERAGE |

55 sq/ft @ 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

n/a |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

DORMANT BLUE (blue/purple look)

| PC1054 |

DORMANT BLUE (BLUE/PURPLE LOOK) |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

3.5-4.5 mils |

| PENCIL HARDNESS |

2-H |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm9 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Dormant Colours need a clear coat for the full colour to come through. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |