SMOOTH FLOWING BLUE PEARLESCENT POWDER.

| MC1023 |

COSMO BLUE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

400F/10 MIN @ PART METAL TEMPERATURE |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

MIDNIGHT COPPER EXPLOSION ~ POLYESTER TGIC ~ DARK COPPER COLOUR THAT FLIPS AROUND WITH BRIGHT COPPER SPARKLES IN THE SUNLIGHT

• CURE TIME = 400F/10 MIN @ PMT (PART METAL TEMPERATURE) • RECOMMENDED MIL THICKNESS = 2.0 – 3.0 MILS • GLOSS LEVEL = 90+% • SPECIFIC GRAVITY = 1.34 • SALT SPRAY RESULTS = 1,000+ HOURS CLEAR COAT RECOMMENDED FOR EXTERIOR APPLICATIONS AND A BETTER GLASS LOOKING FINISH

MIDNIGHT TURQUOISE EXPLOSION POLYESTER TGIC POWDER

DARK TURQUOISE COLOUR THAT FLIPS AROUND WITH BRIGHT BLUE SPARKLES IN THE SUNLIGHT

| CHEMISTRY |

MIDNIGHT TURQUOISE EXPLOSION |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

15 Minutes@ 375°F |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.26 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

FIRESIDE COPPER TOP COAT ~ POLYESTER TGIC ~ IN THE SHADE THIS PRODUCT IS A DEEP BROWN WITH HINTS OF COPPER, AS THE SUN SHINES IT BURNS WITH ALL THE INTENSITY OF THE SUN ITSELF. A BLACK BASECOAT ******BLACK BASECOAT RECOMMENDED

| MC1029 |

FIRESIDE COPPER TOPCOAT |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

15 Minutes@ 375°F |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.2 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

PLUM PEARL

POLYESTER TGIC FREE POWDER

* 10 minutes at 375°F. @ P.M.T. * GLOSS @ 60 DEGREE METER-85+/-3% * RECOMMENDED MIL THICKNESS – 2.5-3.5MILS * SPECIFIC GRAVITY – 1.53 * SALT SPRAY RESULTS – 1,000 HOURS + COVERAGE- 126 sq. ft./lb/1 mi

*** CLEAR COAT NEEDED. EMERALD COATINGS RECOMMENDS A CLEAR FOR PROLONGED EXTERIOR USE AND IMPROVED MAR RESISTANCE.

ROCKSTAR WHITE

A TGIC POLYESTER POWDER THAT HAS A MIXTURE OF MEDIUM TO LARGE GOLD FLAKE THROUGH THE FINISH. GET THE MOST BLING FOR YOUR BUCK

| CHEMISTRY |

ROCKSTAR WHITE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.83 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

ROCKSTAR YELLOW

A TGIC POLYESTER POWDER THAT HAS A MIXTURE OF MEDIUM TO LARGE GOLD FLAKE THROUGH THE FINISH. GET THE MOST BLING FOR YOUR BUCK

| CHEMISTRY |

ROCKSTAR YELLOW |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

ROCKSTAR RED . A TGIC POLYESTER POWDER THAT HAS A MIXTURE OF MEDIUM TO LARGE GOLD FLAKE THROUGH THE FINISH. GET THE MOST BLING FOR YOUR BUCK

| CHEMISTRY |

ROCKSTAR RED |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

ROCKSTAR ORANGE TGIC POLYESTER POWDER

HAS A MIXTURE OF MEDIUM TO LARGE GOLD FLAKE THROUGH THE FINISH. GET THE MOST BLING FOR YOUR BUCK

| CHEMISTRY |

ROCKSTAR ORANGE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

ROCKSTAR BLUE . A TGIC POLYESTER POWDER THAT HAS A MIXTURE OF MEDIUM TO LARGE GOLD FLAKE THROUGH THE FINISH. GET THE MOST BLING FOR YOUR BUCK

| CHEMISTRY |

ROCKSTAR BLUE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

This is a black color with a textured finish. It’s a bit more grainy than our Black Carbide and Deep Flat Black Texture finishes, giving it a slightly rough surface. The finish has a matte look that is not shiny, providing a clean, industrial appearance. The texture is even and smooth to the touch, offering a durable and tough finish. This coating is perfect for surfaces that need to withstand wear and tear while maintaining a neat and professional look. It’s also easy to apply and work with, making it a fan favorite for automotive parts and laser-cut signs.

Recommended Colors With Similar Finishes

If you’re looking for other textured finishes, check out these options:

| PC1021 |

BLACK TEXTURE 7-13% GLOSS |

| CHEMISTRY |

POLYESTER TGIC C |

| REGULAR CURE TEMP |

375F/15 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.50 – 3.50 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.69± 0.03 |

| THEORETICAL COVERAGE |

NA |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6C – Polyester TGIC (Group C) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. USE ZINC RICH PRIMER OVER STEEL PARTS FOR EXTERIOR APPLICATIONS |

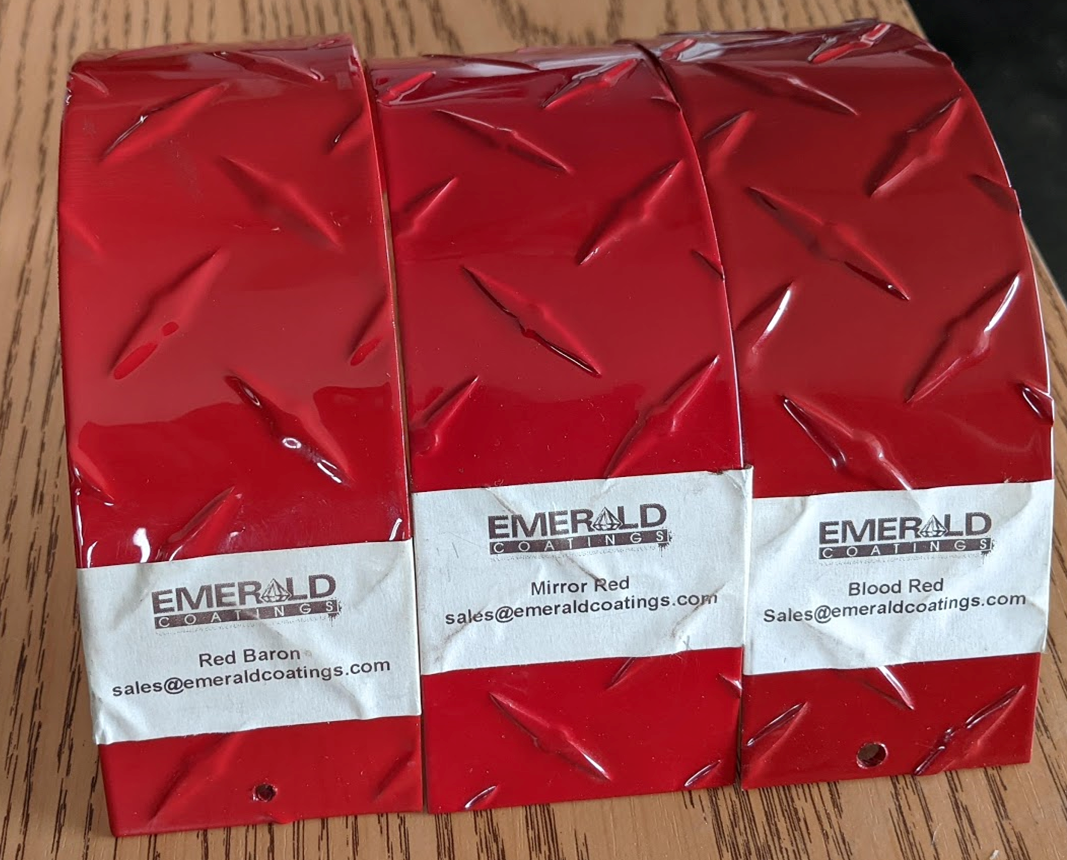

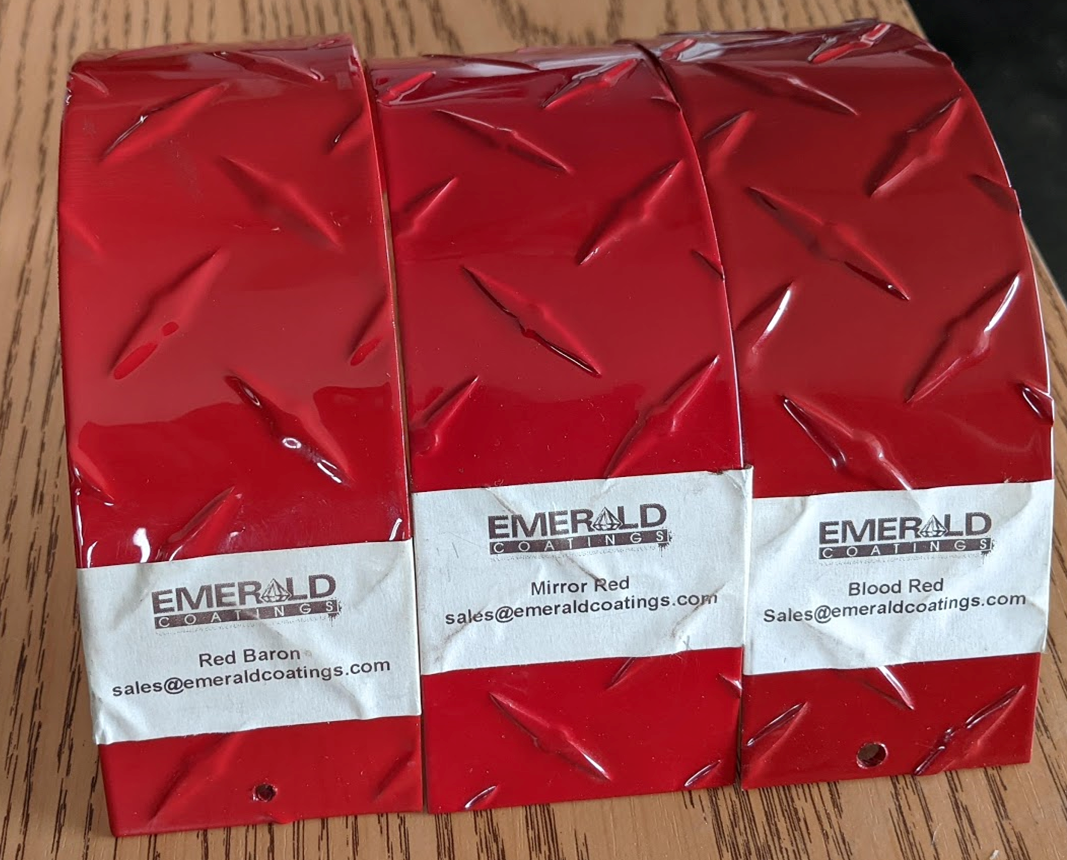

LAYS DOWN SUPER SMOOTH LICK GLASS. EXCELLENT BRIGHT RED. VERY CLOSE MATCH TO MIRROR RED. BLOOD RED IS A SLIGHT DARKER IN COLOUR.

| PC1023 |

BLOOD RED |

| CHEMISTRY |

POLYURETHANE GROUP A |

| REGULAR CURE TEMP |

375F/15 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.9-2.2 mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.3 +/-0.05 g/cm³ |

| THEORETICAL COVERAGE |

147.92 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85+ |

| SALT SPRAY |

2500 |

| BALL IMPACT |

160 |

| SDS Sheet info # |

#5A – Polyurethanes (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. A clear coat is recommended for outdoor applications. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |