Hydrovator

Hydro-Vator is a water transfer printing activator ideal for most films on the market. Formulated perfectly to provide a vibrant image and liquifies in just one pass

For use with most films. Works well with high density/high quality PVA films and is well behaved once applied.

COMBUSTABLE LIQUID

N.O.S.

NA1993, PGIII

HYDROACTIVATOR

EXPRESS CHEM FORMULA

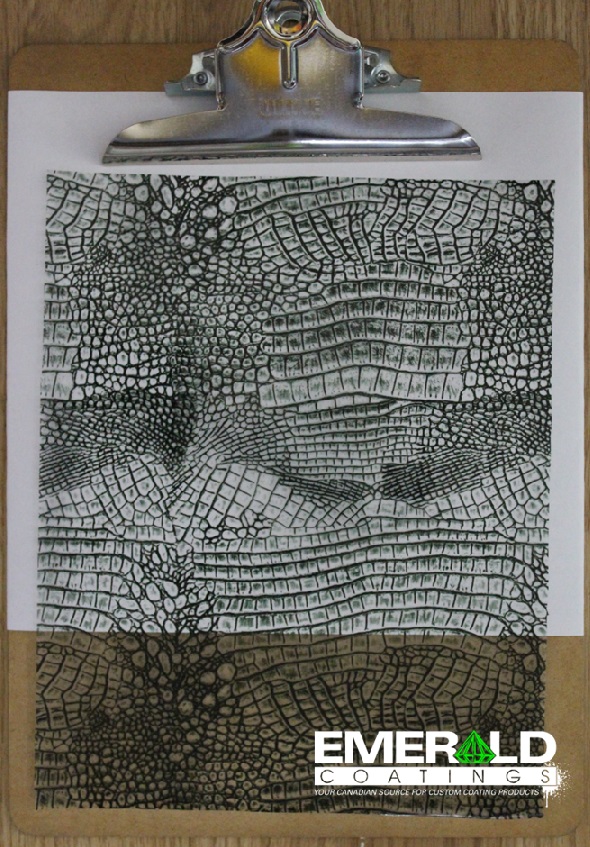

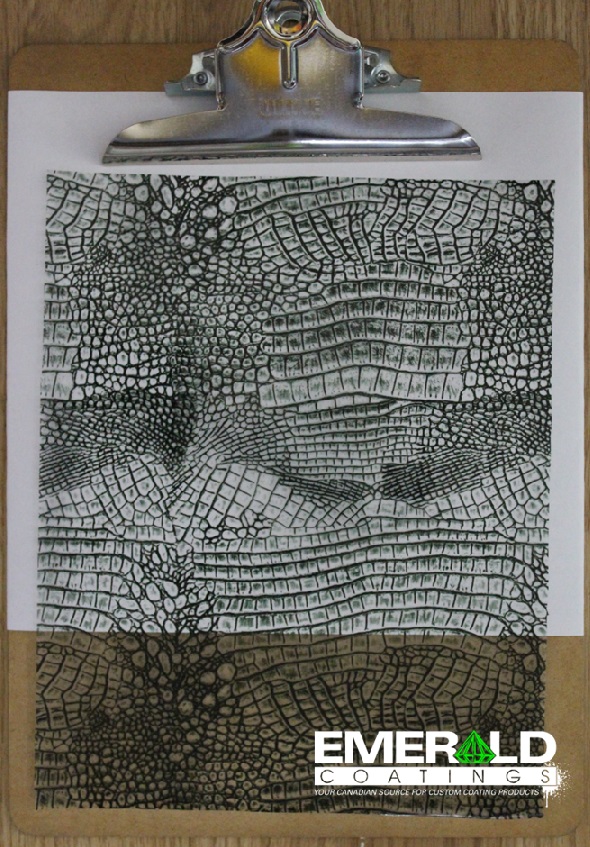

GATOR SKIN 50cm wide

Length per quantity is 5 meters long

We are currently holding a sale on overstock, slow stock, and old stock hydrographic films and paint to make way for some new products. All sale films will be sold in 5-meter rolls at a time. All sale films will be discontinued after they are sold out, once it’s gone it’s gone.

TRUE WEAVE SILVER CARBON FIBER 1m Wide, Silver and Transparent

Length sold by the Meter

Carbon fiber Canadian supplier for hydrographic films

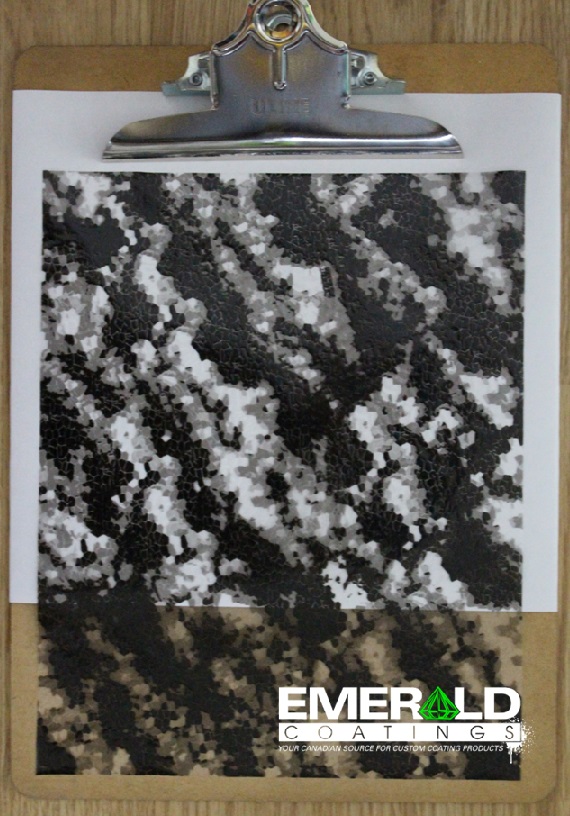

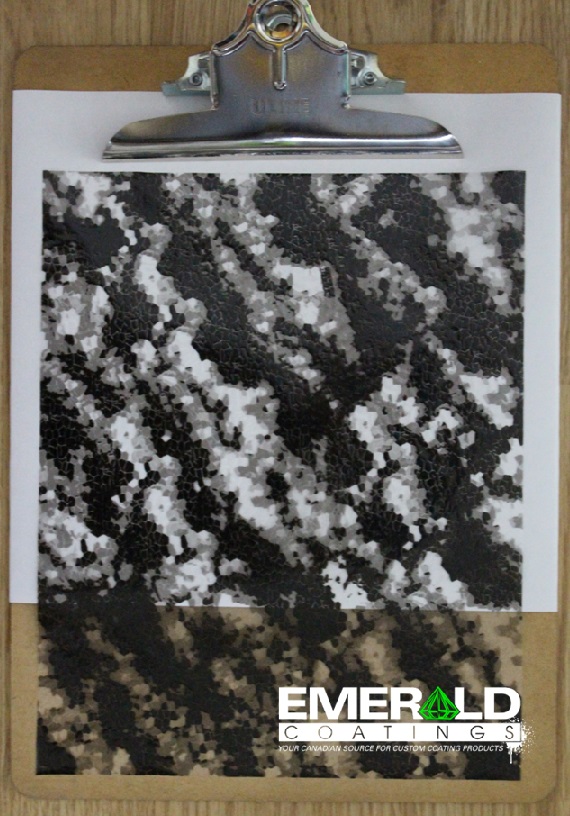

Shaw Naughty Designz Hydrographic film

Length per quantity is 5 meters long

We are currently holding a sale on overstock, slow stock, and old stock hydrographic films and paint to make way for some new products. All sale films will be sold in 5-meter rolls at a time. All sale films will be discontinued after they are sold out, once it’s gone it’s gone.

Works best applied over a black base coat, but can be applied over other colours.

| CHEMISTRY |

MAGIC LILAC TOPCOAT |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.2 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

CLEAR WITH A MICRO PEARL IN THE FINISH

| CHEMISTRY |

MICRO PEARL CLEAR |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 13-20 MIN |

| MIN TEMP |

356F 15-25 MIN |

| MAX TEMP |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.2 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |