The Flapper Adapter mounts onto any angle grinder with a 5/8 – 11 shaft (almost all grinders), and allows you to mount any wheel with a 1/4″ shaft onto your angle grinder. Mount flap wheels, cutoff wheels, buffing wheels, grinding wheels, carbide burrs etc.

Made in the USA. 303 Stainless body with Tool Steel Collets, 1/4″ Collet, and Nut.

Complete set of polishing and buffing accessories for detailing autos, cycles,

boats, RVs, almost anything metal that needs a new look. Includes compound for

polishing all types of metal, mushroom, cylinder and tapered buffs, felt bobs,

spiral sewn buffs and single-stitched buff. All are mounted on a 1/4in. shaft. Includes:

- (1) Black compound

- (1) Green compound

- (1) Brown compound

- (1) White compound

- (1) Blue compound

- (1) Red compound

- (1) Mushroom buff

- (1) Cylinder buff

- (1) Tapered buff

- (2) Spiral-sewn buffs

- (5) Felt buffs

- (1) Single-stiched buff

- (1) Instruction guide

Complete set of polishing and buffing accessories for detailing autos, cycles,

boats, RVs, almost anything metal that needs a new look. Includes compound for

polishing aluminum, mushroom, cylinder and tapered buffs, felt bobs, spiral sewn

buffs and single-stitched buff. All are mounted on a 1/4in. shaft. Includes:

- (1) Black compound

- (1) White compound

- (1) Brown compound

- (1) Mushroom buff

- (1) Cylinder buff

- (1) Tapered buff

- (2) Spiral-sewn buffs

- (5) Felt buffs

- (1) Single-stiched buff

- (1) Instruction guide

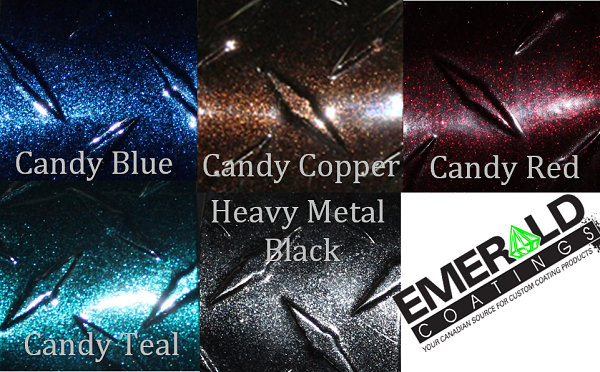

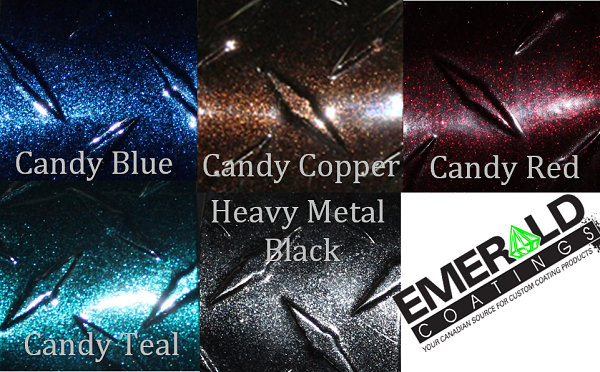

HEAVY METAL BLACK TGIC POLYESTER POWDER

DEEP BLACK WITH A LARGE HEAVY METAL FLAKE.

| MC1035 |

HEAVY METAL BLACK |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE SCHEDULE |

375F / 20 MIN |

| MIN RANGE |

356F / 20 MIN |

| MAX RANGE |

400F / 15 MIN |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.26 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

**ALSO MAKE A GREAT BASE FOR CANDY COLOURS. THE LARGE SILVER FLAKE MAKES THE CANDY COLOUR SPARKLE WHEN IT HITS THE SUN.

Super Bright, super smooth Neon Orange powder. This single stage neon orange is easy to work with an come out super bright. However this is a low UV powder and will fade over time when left in direct repeated sunlight.

| PC1067A |

NEON ORANGE |

| CHEMISTRY |

POLYESTER TGIC |

| REGULAR CURE SCHEDULE |

375F / 20 MIN |

| MIN RANGE |

356F / 25 MIN |

| MAX RANGE |

400F / 15 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

H |

| SPECIFIC GRAVITY |

1.4-1.8 g/cm9 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-90 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| LIMITED UV STABILITY. May fade with repeated outdoor exposure, Even with a clear coat you still may see fading. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. |

Surbuf’s exclusive MicroFingers® technology produces a better finish than traditional hand-rubbed.

Use for staining, waxing, and polishing wood, automobiles, boats, and other solid surfaces.

All oil based wood stains, paste and liquid waxes, surface cleaners, and polishes can be used.

Surbuf® 6 1/2″ R Series pads with MicroFingers® technology for use on 6″ hook base random orbit polisher/sander. Fits Bosch, DeWalt, Festool, Makita, Metabo, Porter-Cable, Ridgid,and all other 6″ hook base random orbit sander/polishers. For woodworking, either the 6″ or 6 1/2″ pad may be used on 6″ base machines for applying finishing products. For Automotive and Marine it is recommended that a 7″ pad be used with 6″ base machines. Use R Series pads for application of finishing products and for buffing. For cleaning a surface, HR9 Series cleaning and buffing pads. Pads are sold two per package.

Key Benefits of Surbuf Pads with MicroFingers®

1. MicroFingers® resist bending and matting to allow cooler, non-burning surface temperatures, which helps protect clear coat finishes.

2. Slim profile easily conforms to different surface contours for maximum coverage and efficiency.

3. Surbuf pads allow for a wide range of operating speeds up to 12,000 opm on ANY solid surface without snagging while reducing the risk of damage to pin striping, decals, and wood tear-out. It also minimizes friction, skipping, and chattering.

4. Hook-and-loop fastening system makes changing pads quick and easy.

5. Edge-to-edge loop fastening accepts various sizes of backing plates providing full hook-to-loop engagement for maximum holding strength and added peripheral edge stability.

6. Low-pad absorption helps make cleaning and polishing products last longer.

7. Surbuf pads can be cleaned easily by hand for on-the-go operations using a comb or soft brush.

SURBUF BROCHURE

Surbuf’s exclusive MicroFingers® technology produces a better finish than traditional hand-rubbed.

Use for staining, waxing, and polishing wood, automobiles, boats, and other solid surfaces.

All oil based wood stains, paste and liquid waxes, surface cleaners, and polishes can be used.

Surbuf® 4″ R Series pads with MicroFingers® technology for use on 4″ hook base random orbit polisher/sanders. Fits Cyclo and all other 4″ hook base polishers. Use R series pads for application of products and for buffing. Pads are sold two per package.

Key Benefits of Surbuf Pads with MicroFingers®

1. MicroFingers® resist bending and matting to allow cooler, non-burning surface temperatures, which helps protect clear coat finishes.

2. Slim profile easily conforms to different surface contours for maximum coverage and efficiency.

3. Surbuf pads allow for a wide range of operating speeds up to 12,000 opm on ANY solid surface without snagging while reducing the risk of damage to pin striping, decals, and wood tear-out. It also minimizes friction, skipping, and chattering.

4. Hook-and-loop fastening system makes changing pads quick and easy.

5. Edge-to-edge loop fastening accepts various sizes of backing plates providing full hook-to-loop engagement for maximum holding strength and added peripheral edge stability.

6. Low-pad absorption helps make cleaning and polishing products last longer.

7. Surbuf pads can be cleaned easily by hand for on-the-go operations using a comb or soft brush.

SURBUF BROCHURE

Surbuf’s exclusive MicroFingers® technology produces a better finish than traditional hand-rubbed.

Use for staining, waxing, and polishing wood, automobiles, boats, and other solid surfaces.

All oil based wood stains, paste and liquid waxes, surface cleaners, and polishes can be used.

Surbuf® 3 1/4″ R Series pads with MicroFingers® technology for use on 3″ hook base random orbit polisher/sanders. Fits Sorby Sandmaster 3″, Metabo SXE 400, and all other 3″ hook base random orbit sander/polishers. Use R Series pads for application of product and for buffing. Pads are sold eight per package.

Key Benefits of Surbuf Pads with MicroFingers®

1. MicroFingers® resist bending and matting to allow cooler, non-burning surface temperatures, which helps protect clear coat finishes.

2. Slim profile easily conforms to different surface contours for maximum coverage and efficiency.

3. Surbuf pads allow for a wide range of operating speeds up to 12,000 opm on ANY solid surface without snagging while reducing the risk of damage to pin striping, decals, and wood tear-out. It also minimizes friction, skipping, and chattering.

4. Hook-and-loop fastening system makes changing pads quick and easy.

5. Edge-to-edge loop fastening accepts various sizes of backing plates providing full hook-to-loop engagement for maximum holding strength and added peripheral edge stability.

6. Low-pad absorption helps make cleaning and polishing products last longer.

7. Surbuf pads can be cleaned easily by hand for on-the-go operations using a comb or soft brush.

SURBUF BROCHURE

Surbuf’s exclusive MicroFingers® technology produces a better finish than traditional hand-rubbed.

Use for staining, waxing, and polishing wood, automobiles, boats, and other solid surfaces.

All oil based wood stains, paste and liquid waxes, surface cleaners, and polishes can be used.

Surbuf® HHR Series 3″ X 5″ hand-held multifunctional applicator & buffing pads featuring MicroFingers®technology. These pads use the same MicroFingers® technology as Surbuf machine pads for efficient product application & cleaning. For woodworking, use this product to apply finishing products such as oils, stains, polyurethane, and other finishing products. For automotive and marine, use to apply tire dressings and cleaning and preservatives to upholstery. For around the home this product is excellent for cleaning dishes, pots, windows, window screens and many other cleaning needs. Pads are sold four per package.

Key Benefits of Surbuf Pads with MicroFingers®

1. MicroFingers® resist bending and matting to allow cooler, non-burning surface temperatures, which helps protect clear coat finishes.

2. Slim profile easily conforms to different surface contours for maximum coverage and efficiency.

3. Surbuf pads allow for a wide range of operating speeds up to 12,000 opm on ANY solid surface without snagging while reducing the risk of damage to pin striping, decals, and wood tear-out. It also minimizes friction, skipping, and chattering.

4. Hook-and-loop fastening system makes changing pads quick and easy.

5. Edge-to-edge loop fastening accepts various sizes of backing plates providing full hook-to-loop engagement for maximum holding strength and added peripheral edge stability.

6. Low-pad absorption helps make cleaning and polishing products last longer.

7. Surbuf pads can be cleaned easily by hand for on-the-go operations using a comb or soft brush.

SURBUF BROCHURE

Description

Brings faded, tarnished and lightly rusted metal accessories back to life. This rejuvenating cleaner + wax saves both time and money by combining restorative and protective properties in one step. Safely removes stubborn discoloration, oxidation, and blemishes. Wipes off to reveal high luster shine and coating that guards against future rust, stains, and weathering. For a variety of automotive metal finishes; coated, non-coated, and non-painted metals-chrome, aluminum, brass, stainless steel and copper. Contains no harsh alkali or acids. Handcrafted and poured in the USA.

Directions

Shake well before using. Surface should feel lukewarm to the touch. Apply THIN amount of No. 850 to a 2X2 ft section at a time with applicator pad. Rub well to loosen all tarnish, rust etc. Reapply as necessary until surface is free of embedded contaminants. When product begins to dry, polish off with dry microfiber or soft cotton towel. See

Tech Sheet for additional tips and instructions.

Applications

-Exterior marine, automotive, motorcycle, RV, and aeronautical metal finishes

-Tarnished chrome, stainless steel, aluminum (non-anodized), brass, and copper(uncoated)

-NOT recommended for painted metals, anodized aluminum

Tech Sheet

Auto product selector guide

Description

An easier-to-use version of the S-238, this heavy-duty pure gel wax is ideal for new and old insulators and bushings, both large and small jobs alike. An excellent choice for fleet maintenance where both lasting protection and timely job completion are paramount. Produces a high gloss finish, increases dielectric strength and performance, repels harmful pollutants and safeguards against flashovers and malfunction. Contains no abrasives or cleaners. Handcrafted and hand-poured in the USA.

Directions

Apply THIN amount of No. 845 to small section at a time with clean, dry applicator pad. As wax dries, polish off with dry cloth or soft cotton towel until a high luster is produced. If surface is soiled or dirty, first apply Collinite’s No. 237 High Voltage Cleaner.

Applications

-Clean bushings and porcelain surfaces of high voltage line insulators

-Electrical/industrial/substation power maintenance use only