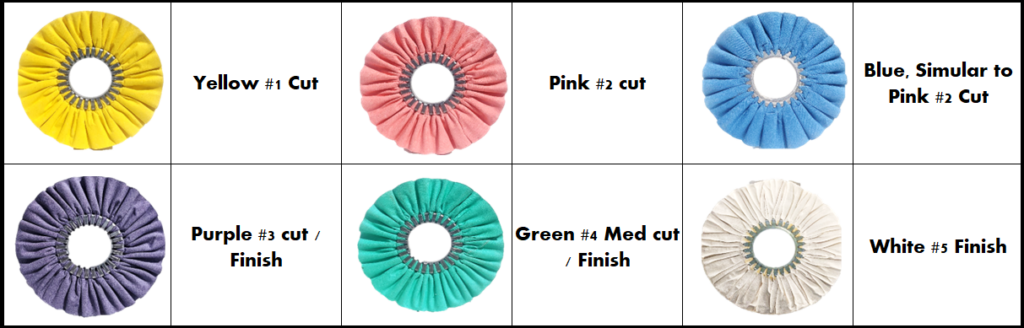

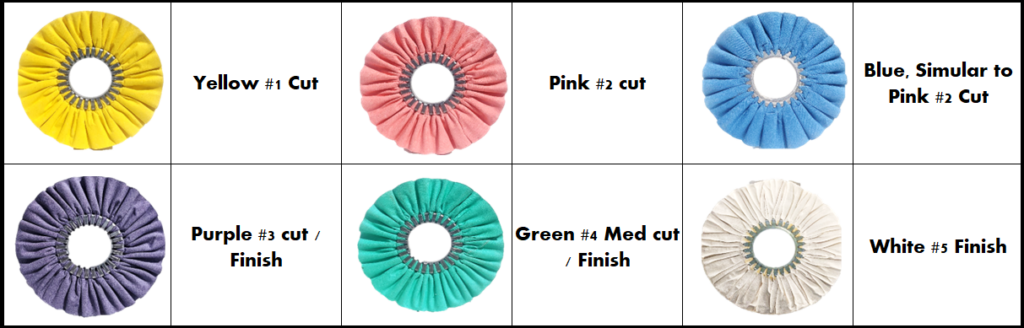

Purple vented buffing wheels. Great mid-wheel for Cut and Finish. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Use the Purple wheel with your favorite heavy cutting bar. If you prefer the Caswell Brand of bars, then use this with the Standard Brown. If you prefer the Marpol Brand of Bars, then use this wheel with the C94 for Stainless steel, Aluminum, and other Alloys or the most popular C106 for stainless steel, brass, non-ferrous metals, aluminum, and alloys

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue

Ballistic Gold is the gold that doesn’t just sit there looking pretty—it demands attention. It’s the color that says, “I’m not here to blend in, I’m here to take over.” This isn’t your average gold; it’s bold, it’s powerful, and it shines like it’s ready for a red carpet entrance. Whether you’re coating automotive parts, industrial machinery, or custom creations, Ballistic Gold will make your project look like it’s been dipped in success. It’s the color for those who want their work to be as badass as they are. Seriously, if gold had a “boss” personality, this would be it.

| PC1186a |

BALLISTIC GOLD |

| CHEMISTRY |

POLYESTER TGIC C |

| REGULAR CURE TEMP |

375F 10 MIN |

| MIN TEMP |

350F 15 MIN |

| MAX TEMP |

400F 7 MIN |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

5B |

| SPECIFIC GRAVITY |

1.18 ±0.06 |

| THEORETICAL COVERAGE |

163ft^2 /lb/mil |

| PENCIL HARDNESS |

5B |

| GLOSS LEVEL (60°) |

85 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#6C – Polyester TGIC (Group C) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Blue vented buffing wheels. These are tougher then the yellow vented wheels and are used for the first cut. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THE 10″ AND 8″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A SAFETY FLANGE

THE 6″ WHEELS HAVE A HARD CENTER WITH A 1/2″ HOLE THAT CAN BE DRILLED TO A LARGER SIZE IF NEEDED.

6″ Velcro Sanding Disc with holes. This is a ceramic grain that provides fast and aggressive cutting action.

Super bright Neon Pink powder coat. This is a polyester TGIC powder, however being a neon it will fade outdoors when exposed to repeated direct sunlight

| PC1123a |

HOT NEON PINK |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

10 Minutes@ 375°F |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2 TO 3 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.55 +/- .05 |

| THEORETICAL COVERAGE |

124 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| This Product may have limited UV stability and may see some fading when used outdoors. Even with a clear coat you still may see fading. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

Description

Lime Squeeze powder coat SD is bright, it’s smooth, and it’s definitely here to shine. Made in a Super Durable formulation, this high-gloss powder is perfect for both interior and exterior applications. Custom made for Emerald Coatings, this is a close match to the Polaris Lime Squeeze. With a vibrant yellow hue that pops and a smooth finish that rivals the best in the business, Lime Squeeze SD is perfect for automotive, outdoor equipment, and custom parts that need to stand out. Whether you’re coating parts that face the elements or adding some flair to your ride, this finish will do it with style and durability. Plus, it’s got that high gloss shine that’ll make you do a double-take.. Another close options is our Manta green, however lime squeeze is a brighter yellow.

| PC1029 |

LIME SQUEEZE POWDER COAT |

| CHEMISTRY |

POLYESTER TGIC |

| REGULAR CURE TEMP |

375F 10 MIN |

| MIN TEMP |

356F 12 MIN |

| MAX TEMP |

400F 7 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.56 |

| THEORETICAL COVERAGE |

123 SQ / FT/LB/1min |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1000 hours |

| BALL IMPACT |

160 in/lb |

| SDS Sheet info # |

Polyester TGIC |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

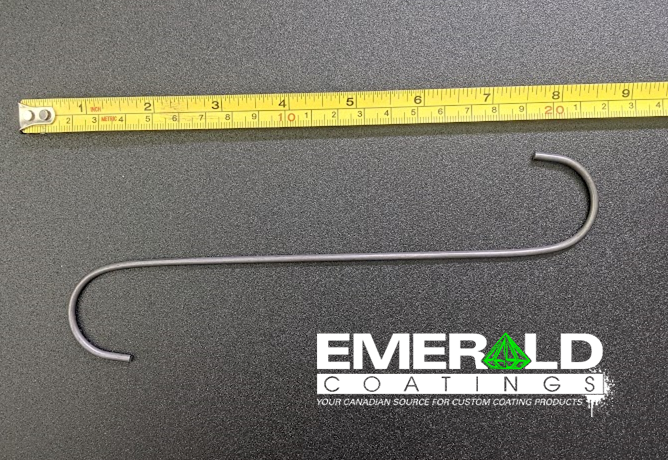

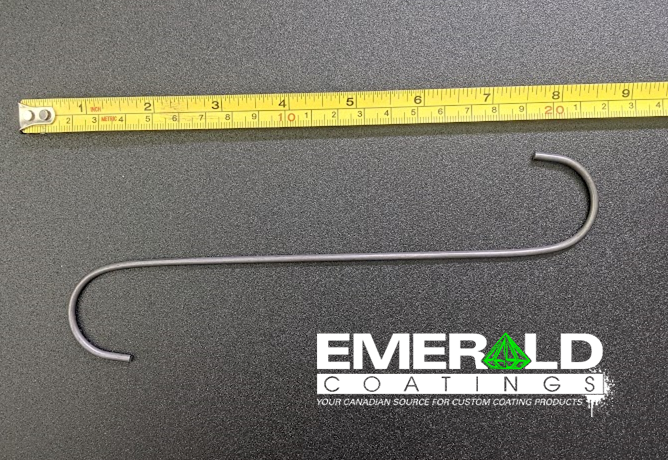

.120 X 8″ LONG S HOOK ( 25 COUNT )

Weight capacity is approximately 30 LBS.

Description

Manta Green powder coat SD is a matched powder to Can-Am’s Manta Green. This high-performance color is specifically designed to match the factory color found on the upper A-arms, inside fender panels, harness bar, and doors of certain Can-Am products. After many requests, we’re thrilled to finally have this Super Durable formula in stock! With its smooth, easy-to-apply finish and high gloss, this single-coat Bright Neon is perfect for those who want that factory-perfect look with a tough, durable finish.

Want the flat version? If you’re looking for the flat finish found on some plastics, simply add our PHANTOM FLAT CLEAR on top to give your Manta Green powder coat that unique flat finish. Whether you’re customizing parts or simply want to refresh your ride, Manta Green SD is here to make a bold statement.

WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS

| PC5000 |

MANTA GREEN POWDER COAT SD |

| CHEMISTRY |

POLYESTER TGIC |

| REGULAR CURE TEMP |

375F 10 MIN |

| MIN TEMP |

356F 12 MIN |

| MAX TEMP |

400F 7 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.56 |

| THEORETICAL COVERAGE |

123 SQ / FT/LB/1min |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1000 hours |

| BALL IMPACT |

160 in/lb |

| SDS Sheet info # |

Polyester TGIC |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| Weather-resistant powder coating for both interior and exterior applications. A clear coat is not required, but can be added for extra protection.Curing Tips: When applying in 2-3 stages, cure the base coat for 50-75% of the recommended time to ensure proper bonding with the top coat. This method results in the best adhesion between layers. Over-curing the base coat may cause delamination. |

Description

Atomic Gold is the color that makes everything else look like it’s in the “B” league. It’s flashy, it’s bold, and it’s got a shimmer that screams, “I’m here to steal the spotlight!” Think of it as the gold medal of powder coatings—because, let’s face it, everything looks better in gold. This color is perfect for when you want your parts to shine brighter than your future. Automotive? Check. Industrial machinery? You bet. Anything that needs a touch of WOW? Atomic Gold is ready to deliver

| pc1076 |

ATOMIC GOLD |

| CHEMISTRY |

POLYESTER TGIC C |

| REGULAR CURE TEMP |

375F 10 MIN |

| MIN TEMP |

350F 15 MIN |

| MAX TEMP |

400F 7 MIN |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.2 ±0.06 |

| THEORETICAL COVERAGE |

156ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6C – Polyester TGIC (Group C) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

OUR NEW SUPER DURABLE VERSION OF OUR POPULAR MIRROR CLEAR

HIGHER IMPACT RATING, HIGHER GLOSS, AMAZING CLARITY AND MEETS A.A.MA. 2604 RATING.

| PC1112SD |

SUPER DURABLE MIRROR CLEAR |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

375F 10-12 MIN |

| MIN TEMP |

356F 15-20 MIN |

| MAX TEMP |

400F 7-10 MIN |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H |

| GLOSS LEVEL (60°) |

100 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

Argento Gunmetal Metallic is the color you use when you want your car, machine, or parts to look like they’re ready to star in a high-budget action movie. It’s the cool shade that says, “I’m serious, but I look damn good doing it.” With its sleek, dark metallic finish, this color strikes the perfect balance between industrial strength and show-stopping style. It’s basically the James Bond of gunmetal colors—sleek, stylish, and never going out of style. If you want something that says, “I’ve got this,” but also “look at me,” this is your color.

THIS NEW PRODUCT OFFERS A HIGHER IMPACT RATING, NON TARNISHING METALLICS AND MEETS OR EXCEEDS A.A.MA. 2603

| PC1005A |

ARGENTO GUNMETAL METALLIC |

| CHEMISTRY |

POLYESTER TGIC-FREE |

| REGULAR CURE TEMP |

375F 10 MIN |

| MIN TEMP |

350F 15 MIN |

| MAX TEMP |

400F 7 MIN |

| RECOMMENDED THICKNESS |

2.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.46 +/- .05 |

| THEORETICAL COVERAGE |

132 sq. ft./lb/1 mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85 |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lb |

| SDS Sheet info # |

#4 – Polyester TGIC Free |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Closest match to our Paccar black. Contact us if you would like us to send out a sample panel before purchasing.

| PC1139a |

SD PAC BLACK SEMI-GLOSS Black |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

400F/10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.5-3.5 mils |

| PENCIL HARDNESS |

2H minimum |

| SPECIFIC GRAVITY |

1.2-1.8 g/cm3 |

| THEORETICAL COVERAGE |

51.5 ft2 /lb at 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

65% |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, clear coat is not needed but will add extra protection. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

**Chrome powders look good but nothing close to real chrome**, This is not a good option if your looking for a real chrome look. Works great as a base for candy colours. Can be used on its own but will need to be clear coated. The clear coat will dull the look down, the product will not hold up without a clear.

| pc1215a |

Auto Krome |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

400F/10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2-H |

| SPECIFIC GRAVITY |

1.55 g/cm3 (± 0.05) |

| THEORETICAL COVERAGE |

NA |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

500 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Needed, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. Chrome powder will tarnish and scratch easy if not clear coated. Cure the base coat around 90% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. Chrome powder can also be top coated with candy colours. |