5″ Velcro Sanding Disc

site info + updates

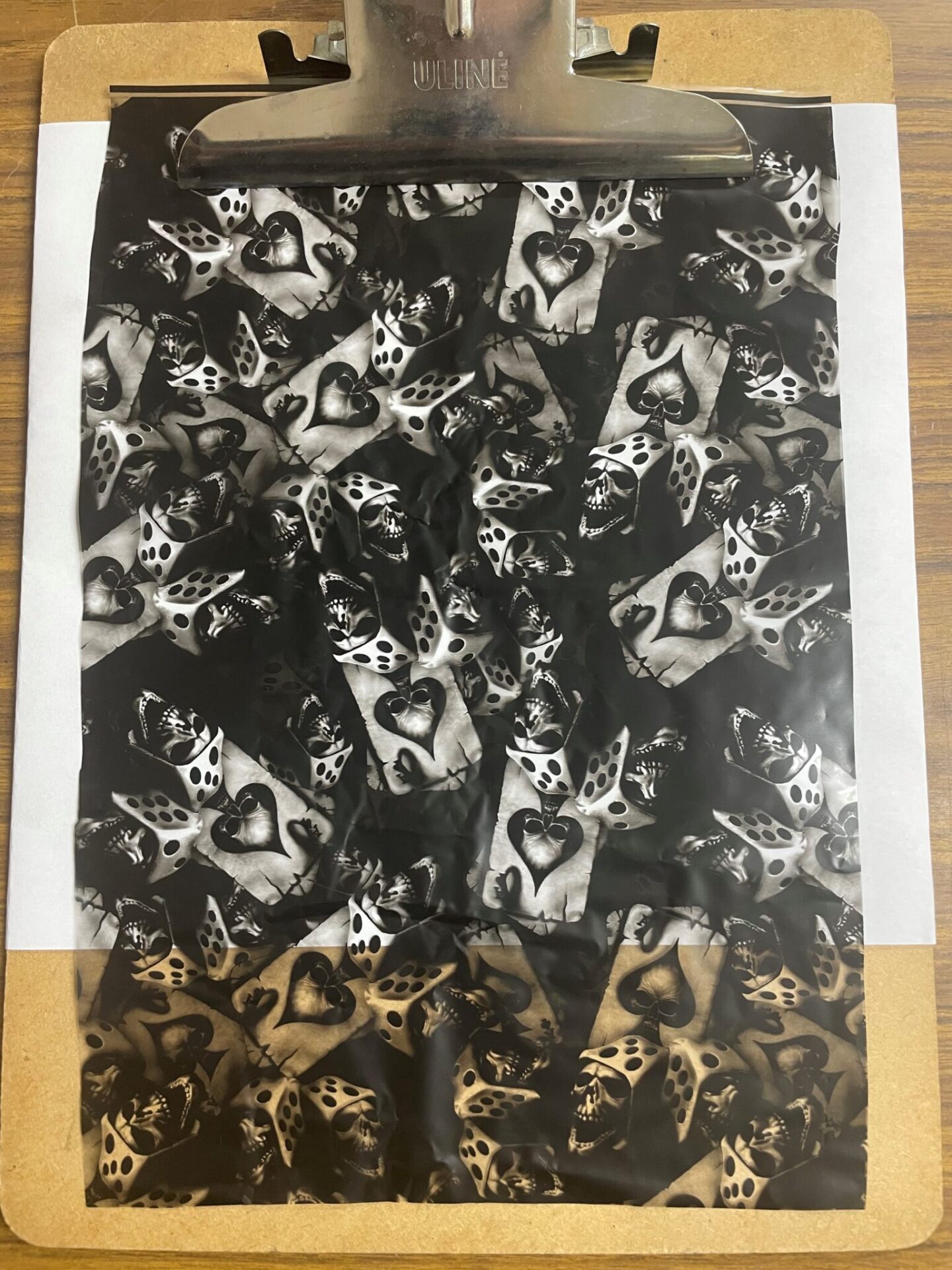

No gambling at all using this awesome high quality film!! Great detail on a film that can be used with so many different items.

This is a black and clear film, different colours will change the overall look of the film. White and Silver would look best but you can use any colour under this film.

This is a 100cm wide film, all films are sold by the Meter

Length per quantity is 5 meters long

We are currently holding a sale on overstock, slow stock, and old stock hydrographic films and paint to make way for some new products. All sale films will be sold in 5-meter rolls at a time. All sale films will be discontinued after they are sold out, once it’s gone it’s gone.

The name of this film says it all!! Great detail on a film that can be used with so many different items.

This is a black and clear film, different colours will change the overall look of the film. White and Silver would look best but you can use any colour under this film.

This is a 100cm wide film, all films are sold by the Meter

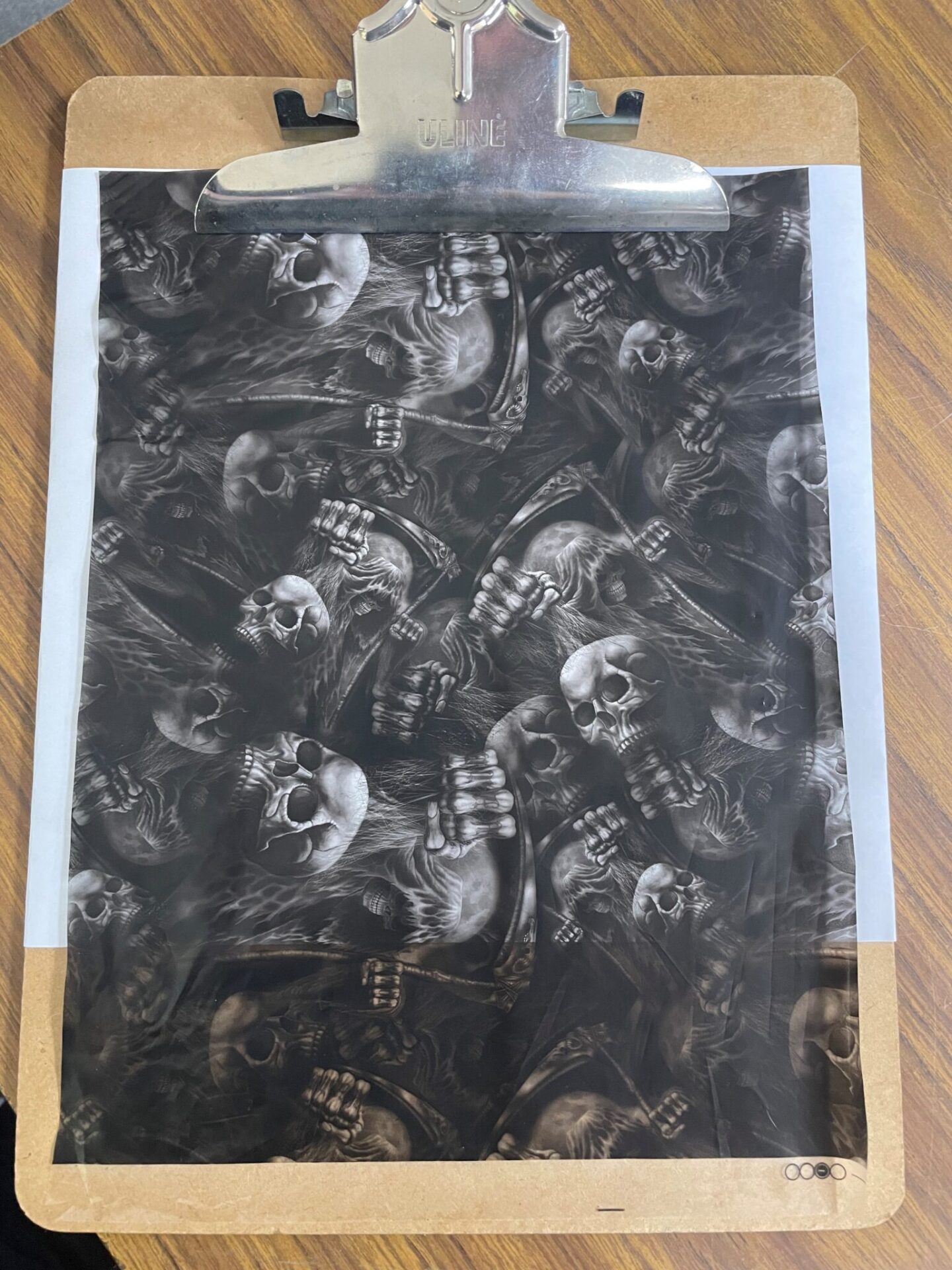

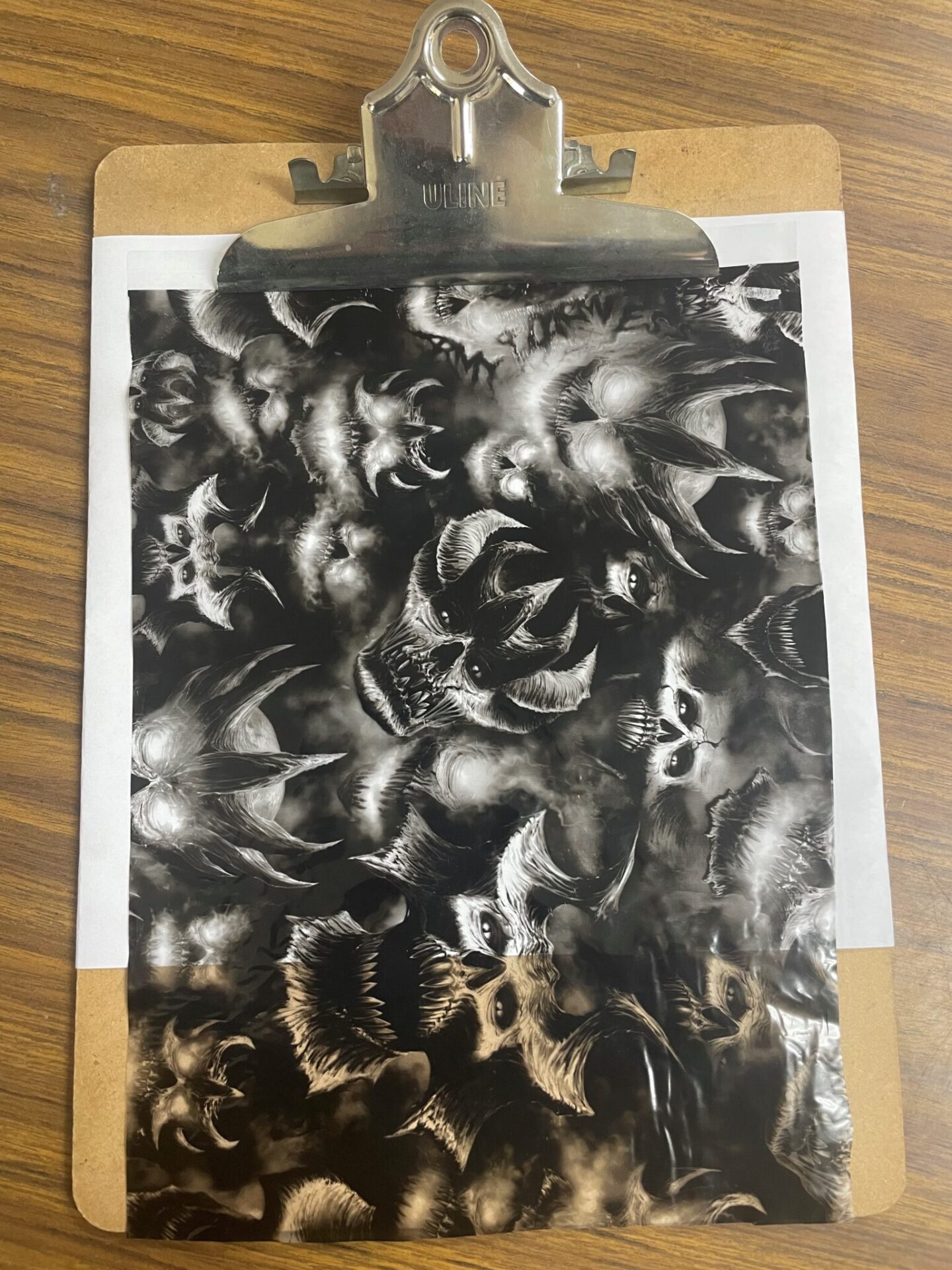

Beautiful film with a creepy aura of Reapers and realistic skulls. Great detail on a film that can be used with so many different items.

This is a black and clear film, different colours will change the overall look of the film. White and Silver would look best but you can use any colour under this film.

This is a 100cm wide film, all films are sold by the Meter

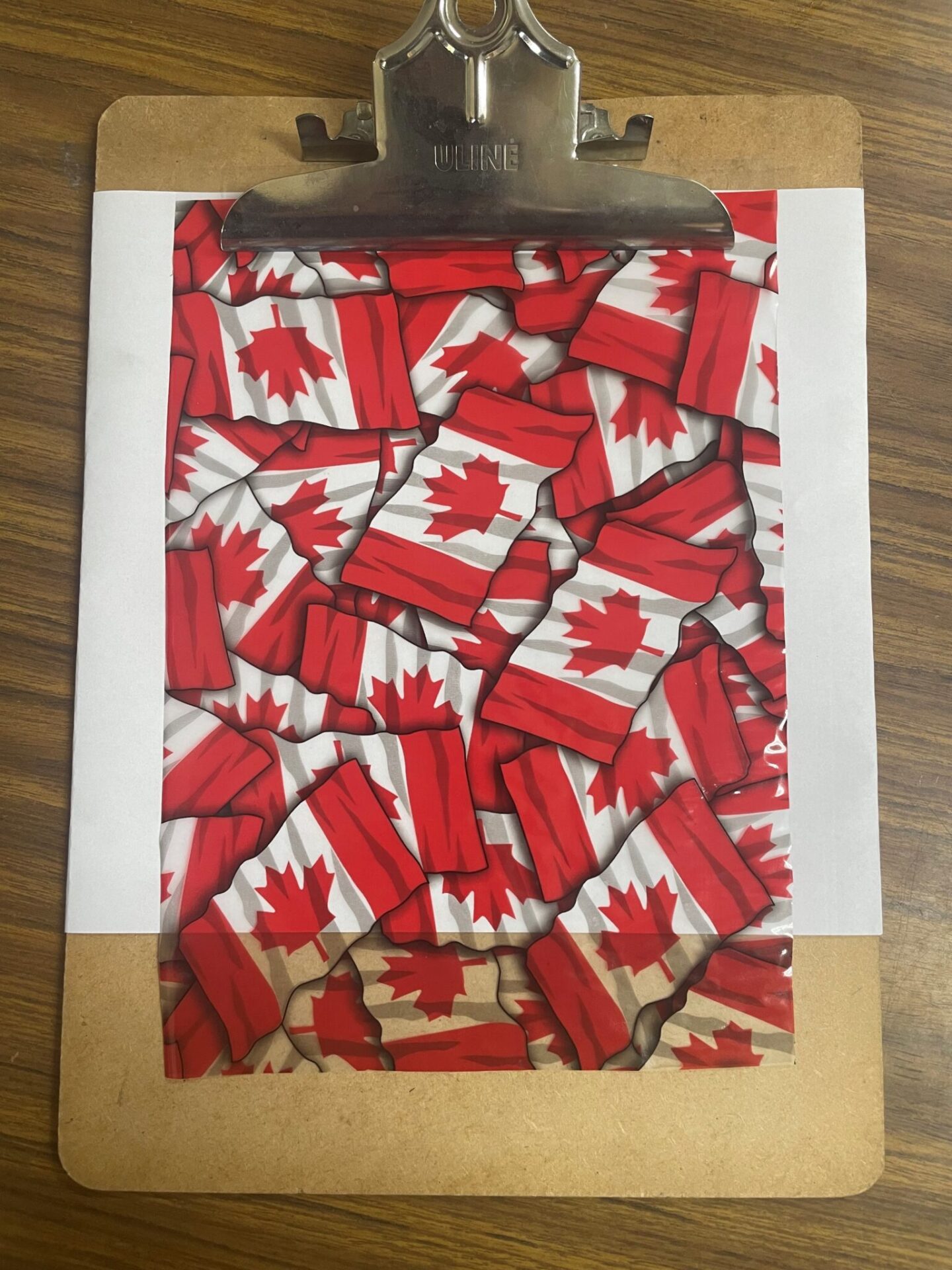

The bold outline of these flags give this image amazing depth and movement. A white base coat is recommended. This gorgeous film can be used for so many applications.

This is a 50cm wide film, all films are sold by the Meter

Low-temp Vinyl masking tape. Great for liquid paints. Not recommended for powder-coating -10° to 80° C (14° – 176° F)

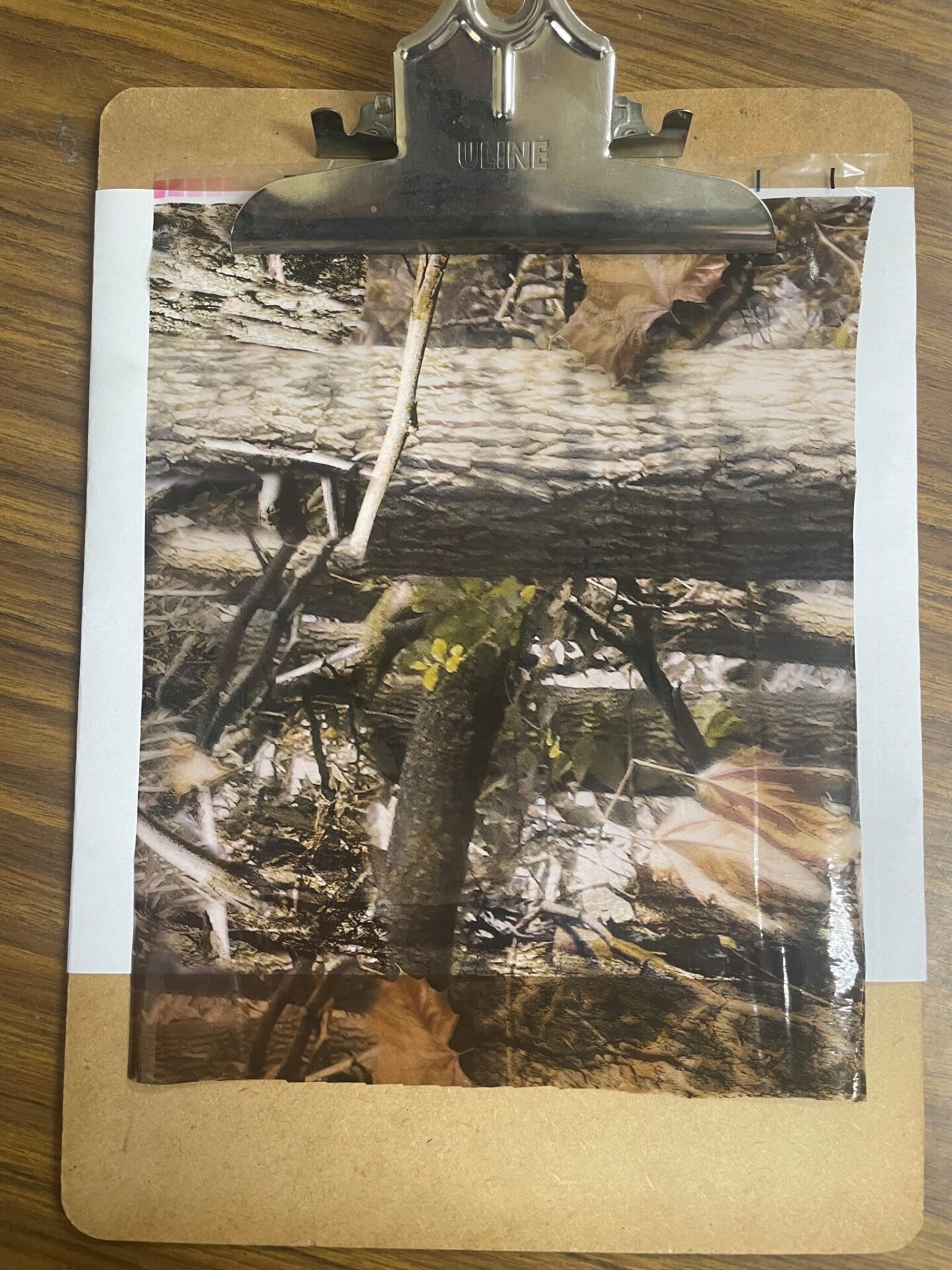

This Camo style film has amazing shades of browns and slight grey, it would be best used over a white basecoat.

Other basecoats may be used but might hide detail in the film.

All films sold by the meter.

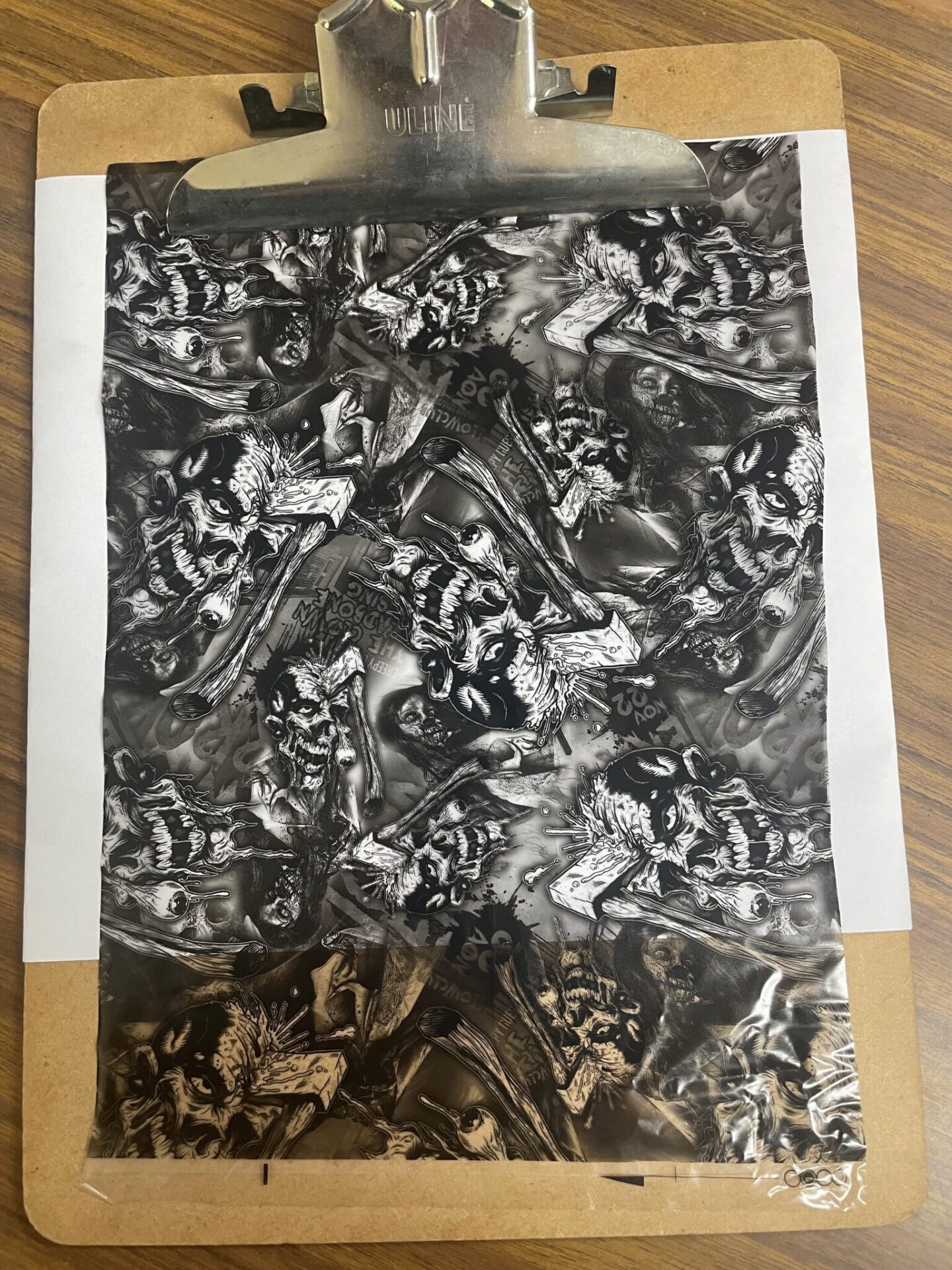

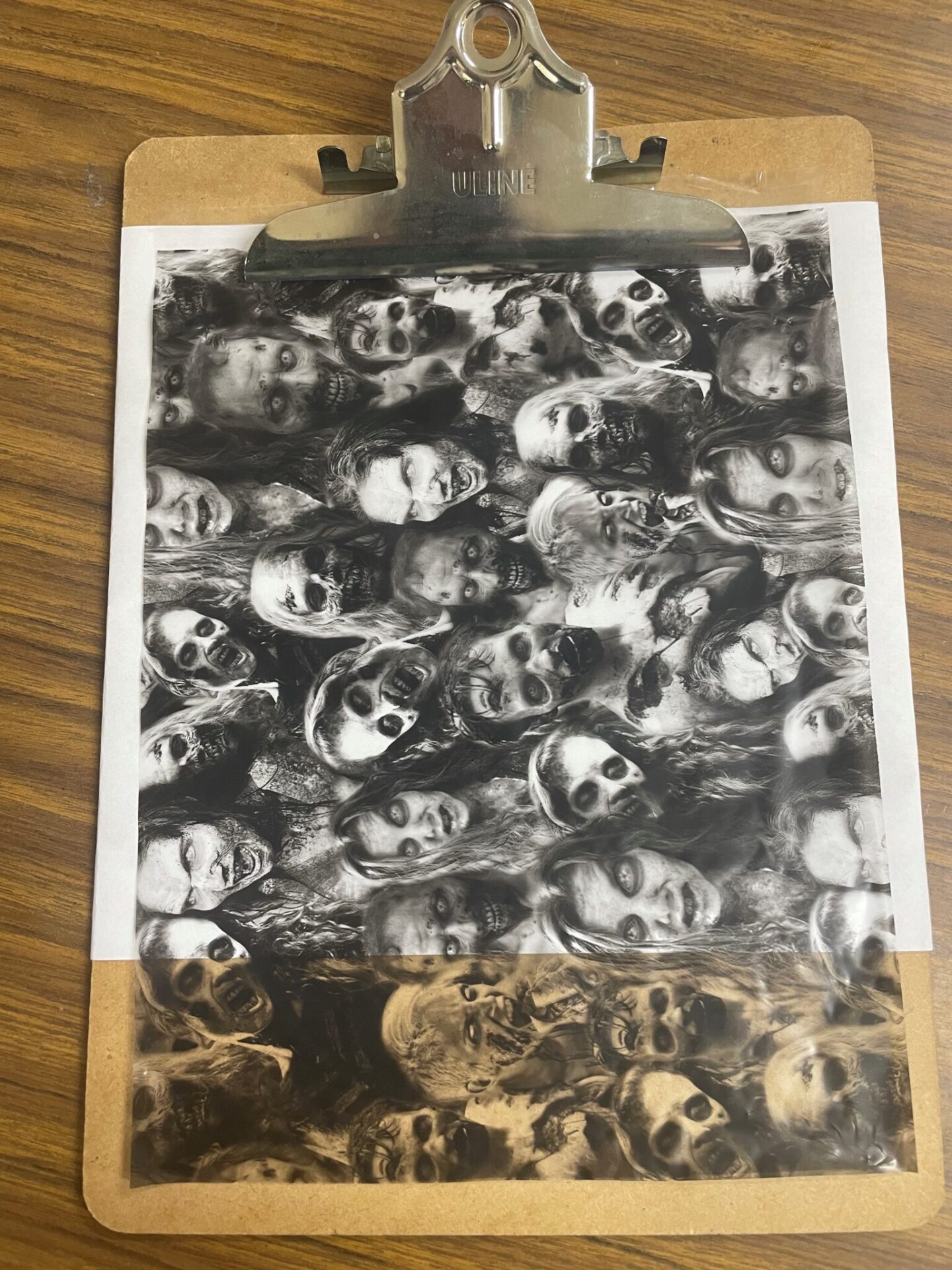

Beautiful film with an army of Zombies. Great detail on a film that can be used with so many different items.

This is a black and clear film, different colours will change the overall look of the film. White and Silver would look best but you can use any colour under this film.

This is a 100cm wide film, all films are sold by the Meter

Beautiful film with an army of creepy beasts. Great detail on a film that can be used with so many different items.

This is a black and clear film, different colours will change the overall look of the film. White and Silver would look best but you can use any colour under this film.

This is a 100cm wide film, all films are sold by the Meter

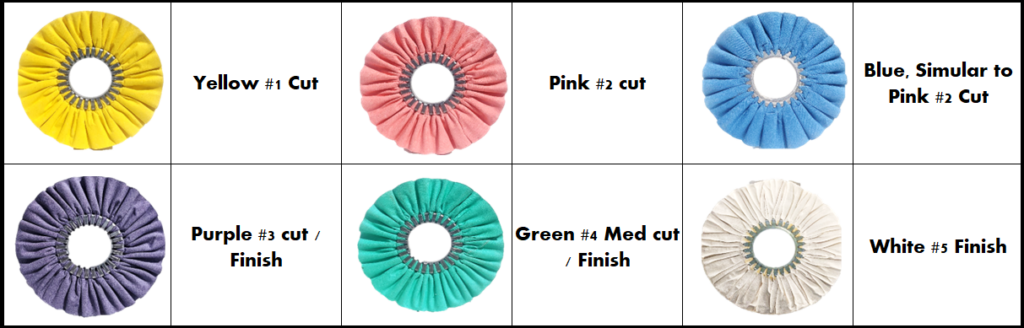

White-vented buffing wheels. The softest of the wheels, used for the final shine. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Use the White wheel with your favorite final polishing bar. If you prefer the Caswell Brand of bars, then use this with the Standard White. If you prefer the Marpol Brand of Bars, then use this wheel with the Volax Chrome (Blue) or the SF15 for a super finish.

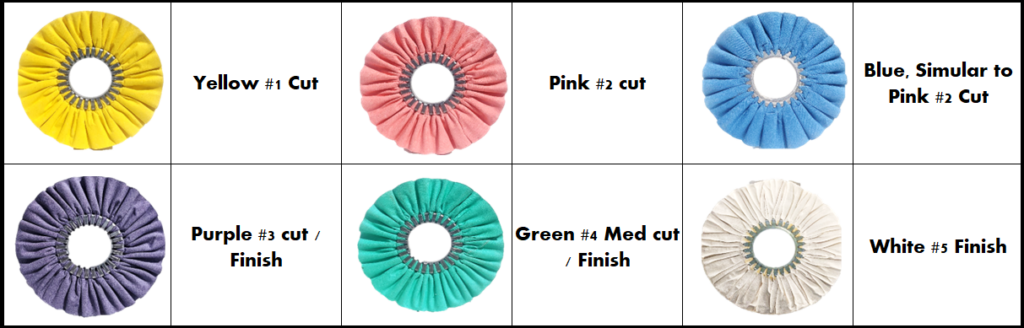

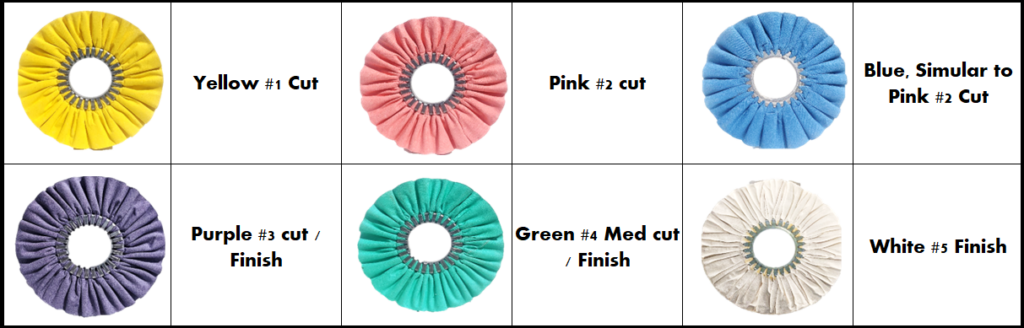

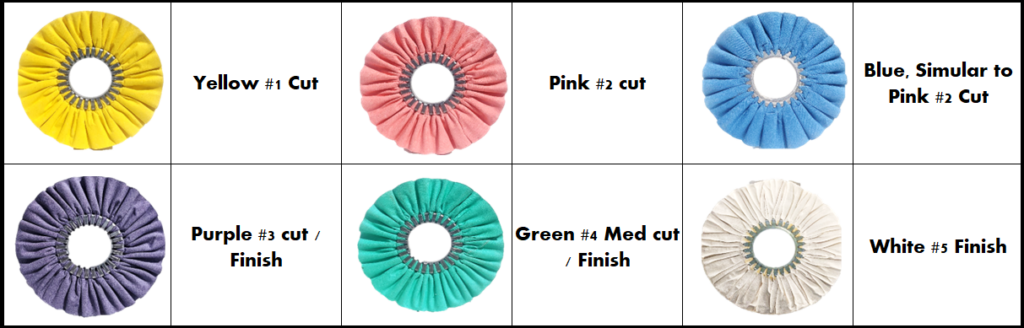

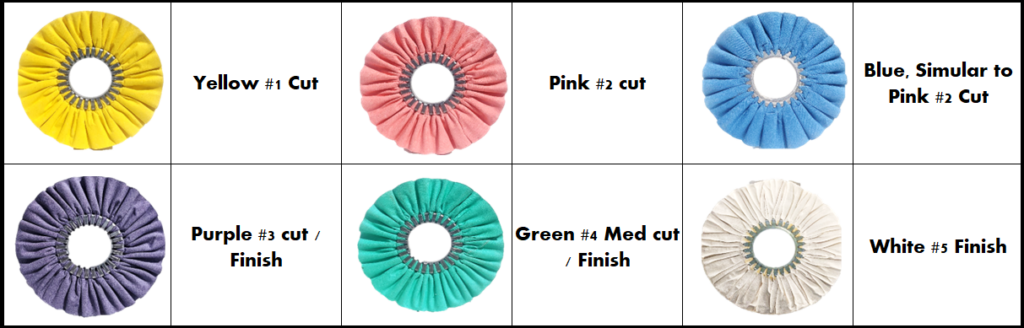

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue

Blue vented buffing wheels. Similar to the Pink, this is used for the second cut. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Use the Blue wheel with your favorite heavy cutting bar. If you prefer the Caswell Brand of bars, then use this with with the Standard Brown or Black. If you prefer the Marpol Brand of Bars, then use this wheel with the C94 for Stainless steel, Aluminum, and other Alloys or the most popular C106 for stainless steel, brass, non-ferrous metals, aluminum, and alloys

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue

Yellow-vented buffing wheels. This is the stiffest wheel of our airway buffs. This very firm wheel is used for heavy cutting on the first cut. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Use the Yellow wheel with your favorite heavy cutting bar. If you prefer the Caswell Brand of bars, the use this with with the Standard Brown or Black. If you prefer the Marpol Brand of Bars, then use this wheel with the C94 for Stainless steel, Aluminum, and other Alloys or the most popular C106 for stainless steel, brass, non-ferrous metals, aluminum, and alloys

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue

Pink vented buffing wheels. Great 2nd Cut. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

Use the Pink wheel with your favorite heavy cutting bar. This wheel is not as stiff as the yellow wheel but still has a fair amount of firmness. If you prefer the Caswell Brand of bars, then use this with the Standard Brown or Black. If you prefer the Marpol Brand of Bars, then use this wheel with the C94 for Stainless steel, Aluminum, and other Alloys or the most popular C106 for stainless steel, brass, non-ferrous metals, aluminum, and alloys

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Gree vented buffing wheels. Great wheel for Med Cut / Finish. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Use the Green wheel with your favorite medium cut/finish bar. If you prefer the Caswell Brand of bars, then us this with with the Standard Brown or white. If you prefer the Marpol Brand of Bars, then use this wheel with the Volax Chrome (Blue)

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue

This is a 2 part safety flange that is required for airway buffs that do not have centers.