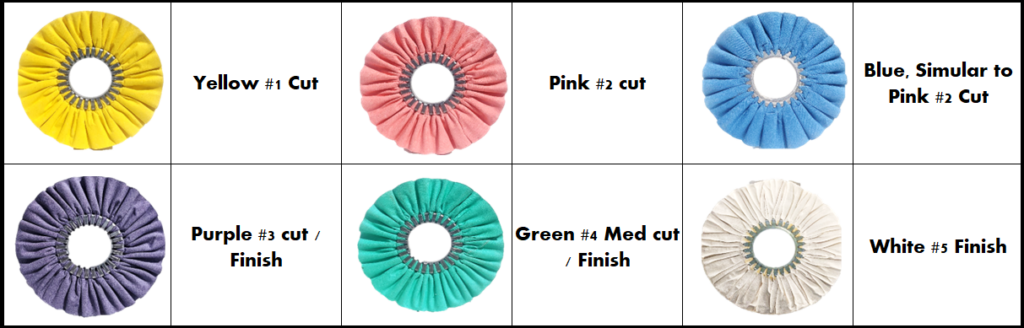

Blue vented buffing wheels. Similar to the Pink, this is used for the second cut. These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler.

THESE 10″ AND 12″ WHEELS HAVE A 3″ CENTER HOLE AND REQUIRE THE USE OF A 3″ SAFETY FLANGE. IF YOU DO NOT HAVE ONE, YOU CAN FIND ONE HERE 3″ SAFETY FLANGE

Use the Blue wheel with your favorite heavy cutting bar. If you prefer the Caswell Brand of bars, then use this with with the Standard Brown or Black. If you prefer the Marpol Brand of Bars, then use this wheel with the C94 for Stainless steel, Aluminum, and other Alloys or the most popular C106 for stainless steel, brass, non-ferrous metals, aluminum, and alloys

What wheels should I use? If you have a lot of cutting or starting with a harder metal, then start with the yellow wheel. For metals in not-so-bad condition, then start with the Blue or Purple.

For most softer metals like aluminum, you can start with Purple, then go to Green then Finish with White. For aluminum that requires more cutting or harder metals, then start with Blue/Pink or Yellow for when heavy cutting is required.

For the most part, you will be able to stick with the Purple, then Green, then White. However, we carry stiffer options like yellow, pink, and Blue