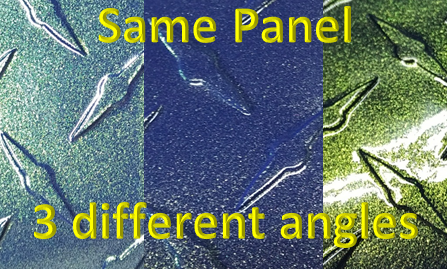

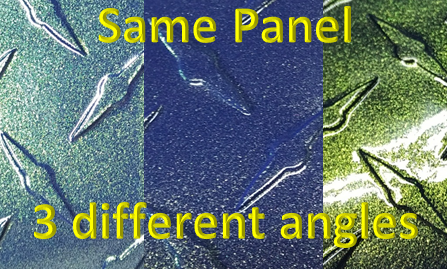

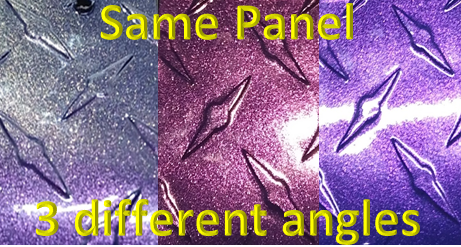

Aqua Shamrock is a Blue Chameleon colour that has metallics that take oven when moved around in the light. Blue Is the main colour seen, but when the sun hits it it has a colour shift of pearls from Green to a Gold Teal to Purple. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| MC1215 |

AQUA SHAMROCK |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.42 +/- .05 |

| THEORETICAL COVERAGE |

68 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

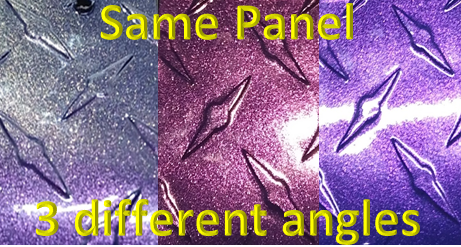

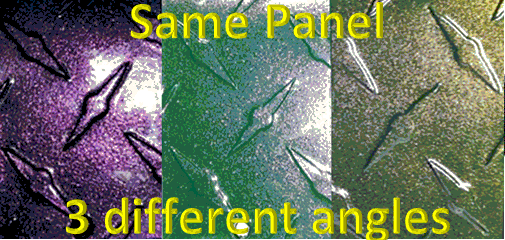

Grape Forest Splash is a Purple Chameleon colour that has metallics that take oven when moved around in the light. Purple Is the main colour seen, but when the sun hits it it has a colour shift of pearls from Different shades of Purple to a Goldish Green. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| MC1211 |

GRAPE FOREST SPLASH |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.42 +/- .05 |

| THEORETICAL COVERAGE |

68 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

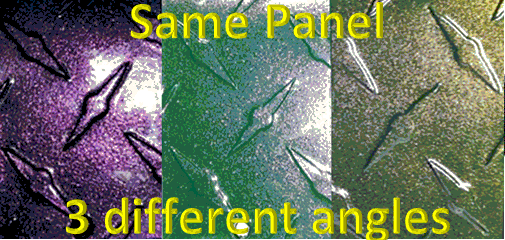

Emerald Lavender is a Green Chameleon colour that has metallics that take oven when moved around in the light. Green Is the main colour seen, but when the sun hits it it has a colour shift of pearls from Purple to Gold to Orange. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| MC1203 |

EMERALD LAVENDER |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.47 +/- .05 |

| THEORETICAL COVERAGE |

66 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

This Camo style film has amazing shades of browns and slight grey, it would be best used over a white basecoat.

Other basecoats may be used but might hide detail in the film.

All films sold by the meter.

This 50cm wide camo style film has great shades of brown and green best used over a white or light coloured base coat.

Other base coats can be used but may hide more details in the film.

All films are sold by the meter.

Treated Spiral Sewn Shank mount wheel 3″ (3″ x 1/2″ x 1/4″ SHAFT)

Cut and colour faster than with regular buffs. Lasts longer than regular buffs.

These new buffs are specially treated to give longer life than standard buffs. This treatment makes them much harder than regular cotton buffs, which allows the user to exert more pressure onto the wheel and gets the job done faster. Use with any compound

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Loose Cotton Shank mount wheel 2.5″ (3″ x 1/2″ x 1/4″ SHAFT)

Gets into cracks and crevices better than Spiral Sewn Cotton Wheels.

The main purpose of a loose cotton wheel is to polish and cut in a similar manner to the Spiral sewn wheel, except that this wheel, not being tightly stitched together, will ‘mush’ or collapse, allowing the cotton to get into awkward places more easily. If you have an object with fine details and awkward crevices, then this is the wheel to use.

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

SHANK MOUNTED WHEEL (2″ x 1/2″ x 1/4″ SHAFT)

Spiral sewn wheels are the workhorse of most buffing and polishing jobs. Because the plies of cotton cloth are sewn together spirally, the wheel becomes much harder and more pressure can be exerted on it. This is especially useful when ‘cutting’ the metal. The faces of these wheels are pre-raked to accept compound immediately

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

SHANK MOUNTED WHEEL (2.5″ x 3/4″ x 1/4″ SHAFT)

Spiral sewn wheels are the workhorse of most buffing and polishing jobs. Because the plies of cotton cloth are sewn together spirally, the wheel becomes much harder and more pressure can be exerted on it. This is especially useful when ‘cutting’ the metal. The faces of these wheels are pre-raked to accept compound immediately

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Spiral Sewn Shank mount wheel 3″ (3″ x 3/4″ x 1/4″ SHAFT)

Spiral sewn wheels are the workhorse of most buffing and polishing jobs. Because the plies of cotton cloth are sewn together spirally, the wheel becomes much harder and more pressure can be exerted on it. This is especially useful when ‘cutting’ the metal. The faces of these wheels are pre-raked to accept compound immediately

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Loose Cotton Shank mount wheel 3″ (3″ x 1/2″ x 1/4″ SHAFT)

Gets into cracks and crevices better than Spiral Sewn Cotton Wheels.

The main purpose of a loose cotton wheel is to polish and cut in a similar manner to the Spiral sewn wheel, except that this wheel, not being tightly stitched together, will ‘mush’ or collapse, allowing the cotton to get into awkward places more easily. If you have an object with fine details and awkward crevices, then this is the wheel to use.

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Spiral Sewn Shank mount wheel 4″ (4″ x 7/8″ x 1/4″ SHAFT)

Spiral sewn wheels are the workhorse of most buffing and polishing jobs. Because the plies of cotton cloth are sewn together spirally, the wheel becomes much harder and more pressure can be exerted on it. This is especially useful when ‘cutting’ the metal. The faces of these wheels are pre-raked to accept compound immediately

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Loose Cotton Shank mount wheel 4″ (4″ x 3/4″ x 1/4″ SHAFT)

Gets into cracks and crevices better than Spiral Sewn Cotton Wheels.

The main purpose of a loose cotton wheel is to polish and cut in a similar manner to the Spiral sewn wheel, except that this wheel, not being tightly stitched together, will ‘mush’ or collapse, allowing the cotton to get into awkward places more easily. If you have an object with fine details and awkward crevices, then this is the wheel to use.

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Spiral Sewn Shank mount wheel 3″ (3″ x 1/4″ x 1/4″ SHAFT)

Spiral sewn wheels are the workhorse of most buffing and polishing jobs. Because the plies of cotton cloth are sewn together spirally, the wheel becomes much harder and more pressure can be exerted on it. This is especially useful when ‘cutting’ the metal. The faces of these wheels are pre-raked to accept compound immediately

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Sisal Shank mount wheel (3″ x 1/2″ x 1/4″ SHAFT)

Sisal is a slender, hard, cellular strand of fiber that has demonstrated its great strength and tough resiliency in the form of binder twine, cord & rope for many years. These qualities, along with its natural abrading and grease absorbing characteristics, provide an ideal buffing wheel fabric.

Sisal buffing wheels will provide both polishing and cutting action. They will remove stretcher strains, orange peel, polishing wheel grit lines, light die marks, etc.

To effect a fast cut, use a Sisal Wheel with the Black Emery compound.

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels

Demin SHANK MOUNTED WHEEL (3″ x 1/2″ x 1/4″ SHAFT)

Our newest buffing wheel, the denim buffing wheel, is soft enough for any buffing application that calls for cotton wheels, but, because of the sturdy denim construction, it lasts much, much longer than a cotton buff.

Up To 5,000 RPM

Great way to buff and polish parts with a cordless drill.

Pick up one of our Extension bit holders to get some extra leverage and flexibility.

Check out the Standard wheel and compound buffing guide for more information on Standard compounds and buffing wheels