This is a Silver backing film that has very little transparency. This means the printed area is silver and the rest is black. You can not change the colour of this print by using different base coats, but you can add a candy top coat to change the colour of this film. This is 1 meter wide print. All films are sold by the meter length.

Cadillac Gunmetal Pearl is a smooth dark Grey gun metal finish with an exceptional pearl luster.

| MC1166 |

CADILLAC GUNMETAL PEARL |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE SCHEDULE |

375F 13-20 MIN |

| MIN RANGE |

356F 15-25 MIN |

| MAX RANGE |

400F 10-15 MIN |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.26 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Stoplight Red

Item: C-143Q

Description:A bright solid tone stop sign red. Stoplight Red is part of the exotic line of C- Series Ceramic Coatings, and will perform at temperatures up to 800F. C-Series coatings are a line of air cured, ready to spray ceramic coatings.

Ceramic coatings designed for specific industries and applications. Not for use on manifolds/exhaust parts

*** PLEASE NOTE STOPLIGHT RED IS ONLY RATED FOR 800*F ***

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

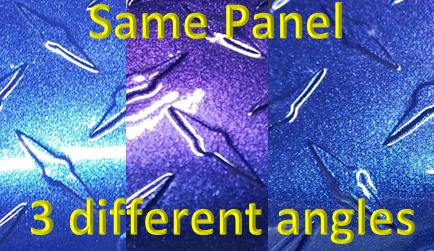

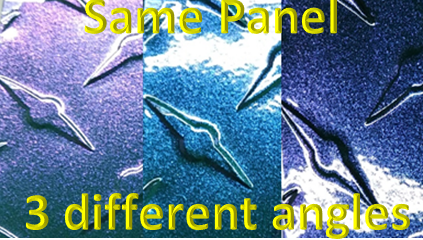

Blueberry Grape is a Blue Chameleon colour that has metallics that take oven when moved around in the light. Blue is the main colour seen, but when the sun hits it, it has a colour shift of different pearls of Blue to Different pearls of Purple. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

This was a hard panel the capture all the different travel and sparkle of the green and gold pearls.

| MC1235 |

BLUEBERRY GRAPE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.42 +/- .05 |

| THEORETICAL COVERAGE |

68 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Ruby Teal is a Ruby Red Chameleon colour that has metallics that take oven when moved around in the light. Ruby Red Is the main colour seen, but when the sun hits it, it has a colour shift of different pearls from Teal to blue to a Mint Green. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

This was a hard panel the capture all the different travel and sparkle of the green and gold pearls.

| CHEMISTRY |

RUBY TEAL |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.41 +/- .05 |

| THEORETICAL COVERAGE |

55 sq/ft @ 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

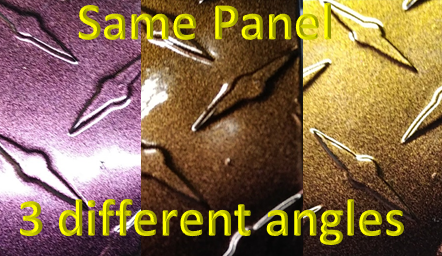

Shamrock Gold is a Green Chameleon colour that has metallics that take oven when moved around in the light. Green Is the main colour seen, but when the sun hits it, it has a colour shift of different shades of green pearls to different shades of gold pearls. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

This was a hard panel the capture all the different travel and sparkle of the green and gold pearls.

| MC1233 |

SHAMROCK GOLD |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.47 +/- .05 |

| THEORETICAL COVERAGE |

66 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

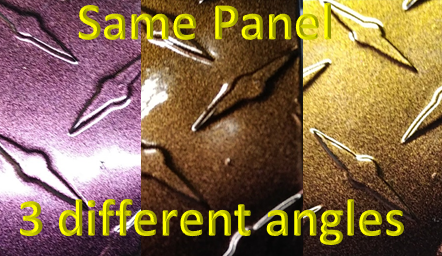

Purple Shift is a Purple Chameleon colour that has metallics that take oven when moved around in the light. Purple Is the main colour seen, but when the sun hits it it has a colour shift of pearls from of Purple to to Orange to Brown. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| CHEMISTRY |

PURPLE SHIFT |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

15 Minutes@ 375°F |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

1.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.26 +/- .05 |

| THEORETICAL COVERAGE |

56 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

80 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

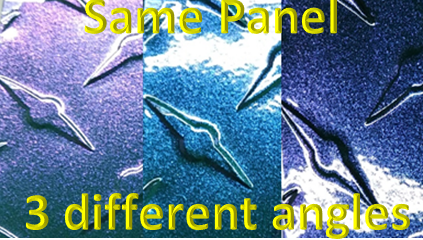

Ruby Sapphire is a Purple Chameleon colour that has metallics that take oven when moved around in the light. Purple Is the main colour seen, but when the sun hits it it has a colour shift of pearls from of Blue to different shades of Purple. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| CHEMISTRY |

RUBY SAPPHIRE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.5 TO 3.5 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.41 +/- .05 |

| THEORETICAL COVERAGE |

55 sq/ft @ 2.5 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Purple Jade is a Green Chameleon colour that has metallics that take oven when moved around in the light. GreenIs the main colour seen, but when the sun hits it it has a colour shift of pearls from of Blue to Teal to Purple. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| CHEMISTRY |

PURPLE JADE |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.47 +/- .05 |

| THEORETICAL COVERAGE |

66 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

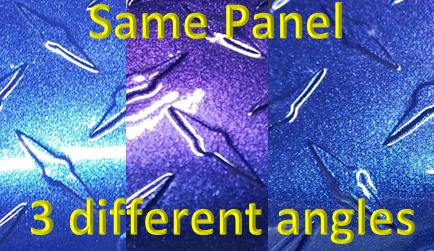

Aqua Teal Chameleon is a Blue Chameleon colour that has metallics that take oven when moved around in the light. Blue Is the main colour seen, but when the sun hits it it has a colour shift of pearls from Different shades of Blue to Teal to a Green. These colours are not for everyone, we suggest buying the Chameleon swatch set before buying this product so you know what these colours look like in person.

https://emeraldcoatings.com/product/chameleon-swatch-set/

| MC1213 |

AQUA TEAL CHAMELEON |

| CHEMISTRY |

Polyester TGIC Metallic |

| REGULAR CURE TEMP |

375F/10 MIN |

| MIN TEMP |

350F/15 MIN |

| MAX TEMP |

400F/7 MIN |

| RECOMMENDED THICKNESS |

2.0 TO 3.0 MILS |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.42 +/- .05 |

| THEORETICAL COVERAGE |

68 sq/ft @ 2.0 mils |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

80-95+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

120 in/lb |

| SDS Sheet info # |

#9 – Polyester TGIC Metallic |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |