$28.00

Description

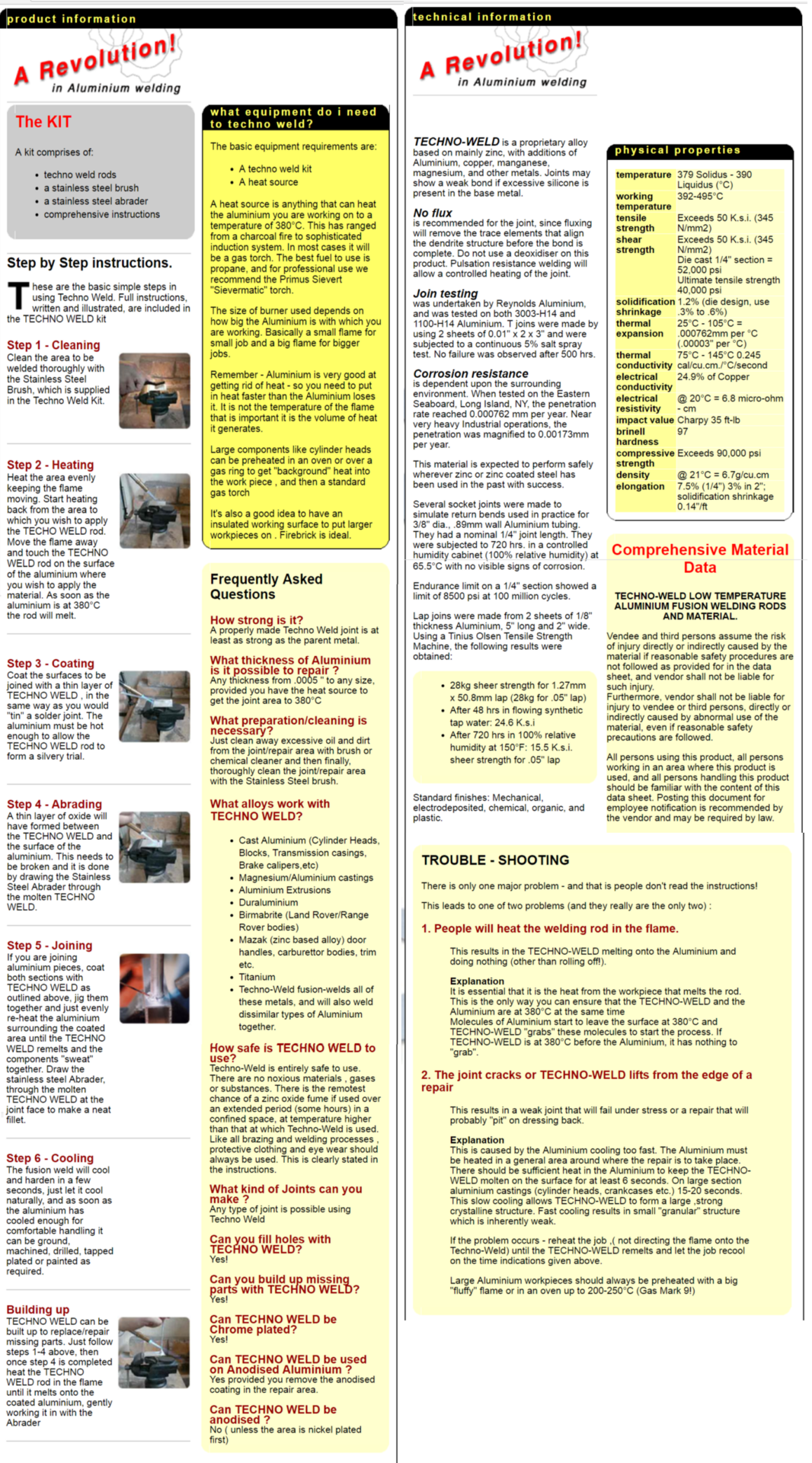

TECHNO-WELD can be used to weld aluminum parts quickly and easily, at a low temperature. TECHNO-WELD is a revolutionary material in the field of Aluminum Joining, and overcomes some of the major problems associated with traditional methods.

SIMPLE TO USE – Joining with TECHNO-WELD is a similar process to gas soldering/silver soldering, therefore traditional Aluminum welding skills are not necessary. Like soldering, it is a two stage process, where the first stage is to heat the work piece to 380C and ‘tin’ the surfaces to be joined with the TECHNO-WELD rod – the TECHNO-WELD alloy diffuses into the surface, changing the composition and reducing the melting point of the parent alloy. The second stage is to reheat the mated surfaces to 380°C, allowing the surface layers to fuse together. Any general heat source appropriate to the job can be used, such as an Air-Acetylene or Air-Propane Blowtorch. No need to raise the temperature of the job dangerously near the melting point of the Alloy itself, avoiding the possibility of sudden collapse of the job.

NO FLUX/FLUX FUMES – The process requires no Flux at all, and is therefore free from toxic flux fumes There is no need for special cleaning processes after the work has been done. Any joints that have been prepared with TECHNO-WELD can be ground back and painted or plated without the possibility of the coating ‘spoiling’ due to flux migration.

A STRONG FUSION WELD – TECHNO-WELD forms a true Fusion Weld. Although the welder is not heating the work piece up to it’s melting point, the area of work piece under the correctly applied TECHNO-WELD will melt and form an alloy with the TECHNO-WELD material without high local temperatures. The resultant material is very hard (like a soft version of mild steel), has good tensile and compressive strengths which serves to reinforce the join or filled area.

Additional information

| Weight | 3 lbs |

|---|---|

| Dimensions | 6 × 6 × 6 in |