Axalta FF Super Silver II is the superstar of silvers—bright, clean, and super easy to spray. This is our most popular silver, it delivers the brightest, cleanest metallic finish. It’s perfect for OEM silver rims and gives any project a sleek look that pops out. It is also the powder of choice when using a base coat for candy colors.

Check out our Wheel Silver if you need something just as clean but not as flashy.

| PC1212 |

Axalta FF SUPER SILVER II |

| CHEMISTRY |

Polyester TGIC (AXALTA) |

| REGULAR CURE TEMP |

400F 10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.2 ±0.05 |

| THEORETICAL COVERAGE |

154ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

65+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

140 in/lb |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

Axalta Diamond Dust is our most popular high gloss clear coat, providing a smooth, glossy finish with incredible clarity. It flows our great and is easy to work with, Perfect for use over metallic’s. Like Most high gloss clears, this will have a slight yellowish hue if applied to heave or applied over whites. This clear coat is ideal for automotive parts, machinery, and custom projects. There is a reason this had become our most popular clear. Even though this is our most popular clear we do have lots of other options, check out our full Clear Coat Comparison Chart to compare this with other clear finishes and find the perfect match for your needs!

AXALTA DIAMOND DUST (PFC602S9 )

| PC1219a |

DIAMOND DUST |

| CHEMISTRY |

Polyester TGIC (AXALTA) |

| REGULAR CURE TEMP |

400F 10-15 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-2.5 mils |

| PENCIL HARDNESS |

H |

| SPECIFIC GRAVITY |

1.2 ±0.05 |

| THEORETICAL COVERAGE |

160 ft /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

100+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lb |

|

|

|

|

| Weather-resistant powder coating suitable for both interior and exterior applications.

When applying in 2-3 stages, it is recommended to cure the base coat for 50-75% of the recommended time. This allows the top coat to properly bond with the base coat. As a result, this method ensures the best possible cross-linking and bond between the coats. However, over-curing the base coat may cause potential delamination between layers. |

make an informed choice!

Description

High Gloss Cat Black powder, is the gloss black that gets the job done—and then some. It’s our most popular gloss black, and for good reason. This color flows out like glass, leaving behind a flawless, high-shine finish that’ll make your parts look like they’ve been dipped in luxury. Not only is it easy to work with, but it’s also officially approved by CAT as their gloss black, meaning it’s tough enough for the big leagues. Whether you’re coating automotive parts, machinery, or anything that needs that perfect glossy touch, High Gloss Cat Black delivers results that are both sleek and durable.

Looking for similar finishes? Check out AK MIRROR BLACK, PHANTOM GLASS BLACK AND ral 9005 JET BLACK – All cool options but not as popular as the, HIGH GLOSS CAT BLACK

AXALTA HIGH GLOSS CAT BLACK (PFB610S9) EXCELLENT HIGH GLOSS SMOOTH BLACK FINISH FROM AXALTA POWDER COATING.

| PC1201 |

HIGH GLOSS CAT BLACK |

| CHEMISTRY |

POLYESTER TGIC |

| REGULAR CURE TEMP |

400F 10 MIN |

| MIN TEMP |

N/A |

| MAX TEMP |

N/A |

| RECOMMENDED THICKNESS |

1.5-2.0 Mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.23+/- 0.05 |

| THEORETICAL COVERAGE |

156 ft 2/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

85+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

100 in/lb |

|

|

|

|

| Weather-resistant powder coating for both interior and exterior applications. A clear coat is not required, but can be added for extra protection.Curing Tips: When applying in 2-3 stages, cure the base coat for 50-75% of the recommended time to ensure proper bonding with the top coat. This method results in the best adhesion between layers. Over-curing the base coat may cause delamination. |

PLEASE NOTE: THIS PRODUCT MAY LOOK BLUE, BUT WILL CURE TO A DEEP BLACK FINISH.

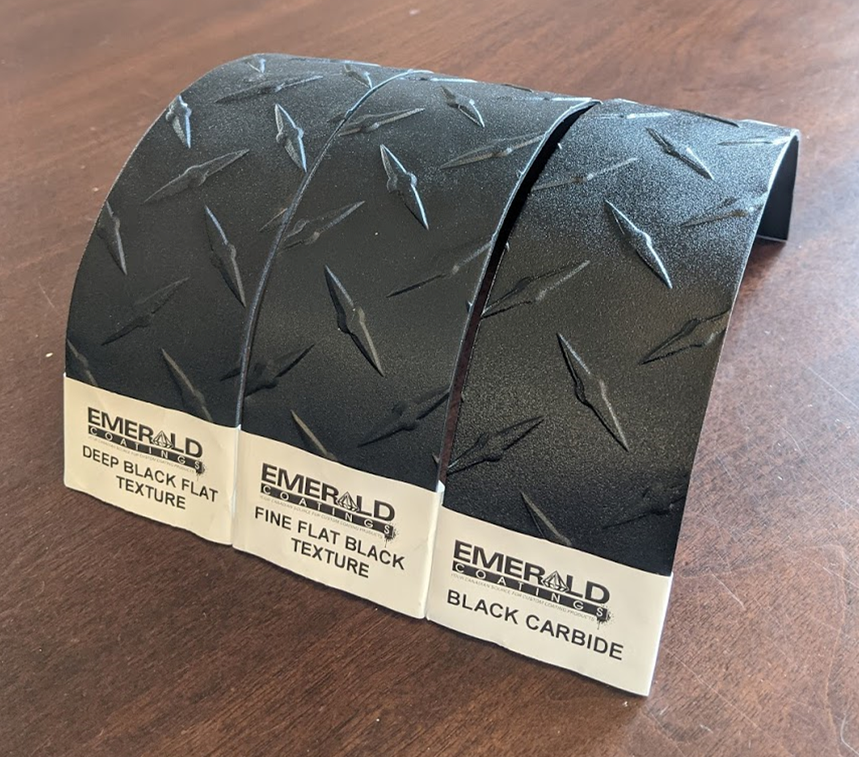

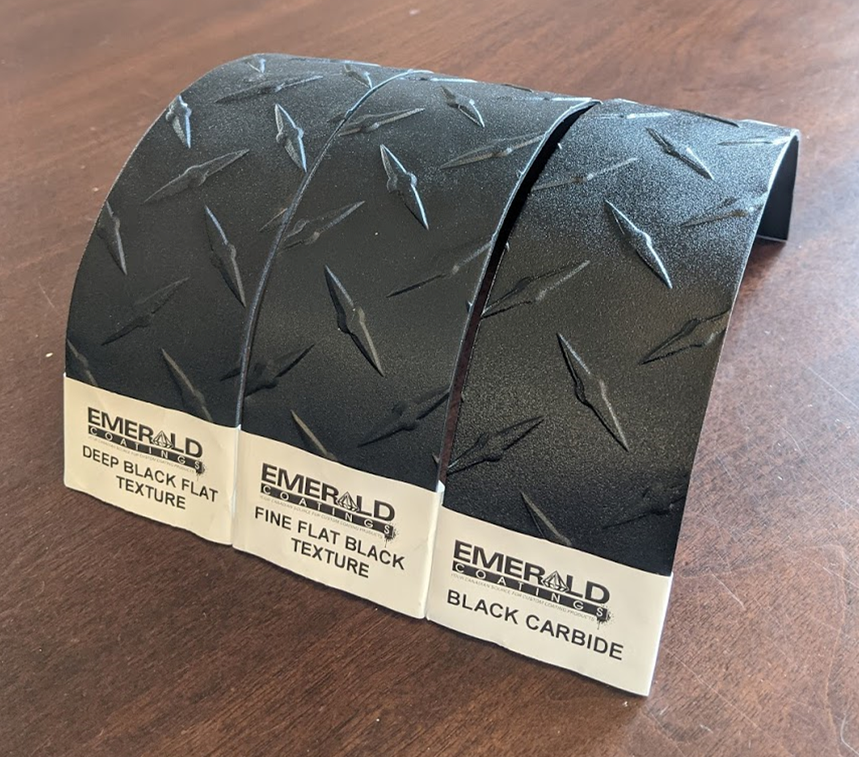

CAN’T FIGURE OUT WHAT BLACK TEXTURE TO GET?

Deep black texture, is a very fine texture with a very flat look to it.

Black carbide, also a fine texture, has a much cleaner/richer black look.

Our personal opinion, carbide black has a nicer look to it, but the deep black texture is much more flatter in gloss. Both are great powders that are easy to use and work with. LOOK AT THE PICTURES BELOW FOR MORE INFO

| PC1174 |

DEEP BLACK FLAT TEXTURE |

| CHEMISTRY |

POLYESTER TGIC A |

| REGULAR CURE TEMP |

400F/10 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

5b |

| SPECIFIC GRAVITY |

1.45 +/- 0.05 |

| THEORETICAL COVERAGE |

133 FT2/LB/MIL |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lb |

| SDS Sheet info # |

#6A – Polyester TGIC (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| PLEASE NOTE: THIS PRODUCT MAY LOOK BLUE, BUT WILL CURE TO A DEEP BLACK FINISH. WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS |

AXALTA STARDUST SILVER III (PFA639B6) SMOOTH LOOKING SILVER FROM AXALTA POWDER COATING. ALSO VERY CLOSE MATCH TO MIRROR SILVER.

| PC1145a |

Stardust Silver III |

| CHEMISTRY |

Polyester TGIC (AXALTA) |

| REGULAR CURE TEMP |

400F 10-15 MIN |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.49 ± 0.05 |

| THEORETICAL COVERAGE |

129ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

NA |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

160 in/lb |

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. |

NEW AND NOW IN STOCK!!!!!! BRIGHT VIBRANT CANDY RED

JOLLIPOP CANDY RED FROM AXALTA (PFR637S9) EXCELLENT HIGH GLOSS SMOOTH CANDY RED FINISH. NEEDS A BRIGHT SILVER OR CHROME BASE COAT, FOR SILVER WE RECOMMEND USING THE FF SUPER SILVER II

| PC1137 |

Jollipop Candy Red |

| CHEMISTRY |

POLYESTER TGIC Axalta |

| REGULAR CURE TEMP |

400F/10 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

H |

| SPECIFIC GRAVITY |

1.22 +/- .05 |

| THEORETICAL COVERAGE |

158ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

90+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

100 in/lb |

| SDS Sheet info # |

SDS JOLIPOP RED AXALTA |

| SDS link |

SDS JOLIPOP RED AXALTA |

| This Product is transparent and will show the base coat through the finish. It is recommended to spray over a metallic silver or chrome powder. This can also be used over polished surfaces with out a base coat. Applying over a polished surface will have the highest shine, however applying over polished or chrome surfaces may be more prone to chipping. Candy / transparent colours are considered tinted clear coats and have the durability and protection of a regular clear coat. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. |

NEW AND NOW IN STOCK!!!!!! BRIGHT VIBRANT CANDY BLUE

JOLLIPOP CANDY BLUE FROM AXALTA EXCELLENT HIGH GLOSS SMOOTH CANDY BLUE FINISH. NEEDS A BRIGHT SILVER OR CHROME BASE COAT, FOR SILVER WE RECOMMEND USING THE FF SUPER SILVER II

| PC1060 |

Jollipop Blue |

| CHEMISTRY |

POLYESTER TGIC Axalta |

| REGULAR CURE TEMP |

400F/10 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

H |

| SPECIFIC GRAVITY |

1.22 +/- .05 |

| THEORETICAL COVERAGE |

158ft^2 /lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

90+ |

| SALT SPRAY |

1,000 hours |

| BALL IMPACT |

100 in/lb |

| SDS Sheet info # |

SDS JOLIPOP BLUE AXALTA |

| SDS link |

SDS JOLIPOP BLUE AXALTA |

| This Product is transparent and will show the base coat through the finish. It is recommended to spray over a metallic silver or chrome powder. This can also be used over polished surfaces with out a base coat. Applying over a polished surface will have the highest shine, however applying over polished or chrome surfaces may be more prone to chipping. Candy / transparent colours are considered tinted clear coats and have the durability and protection of a regular clear coat. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. |

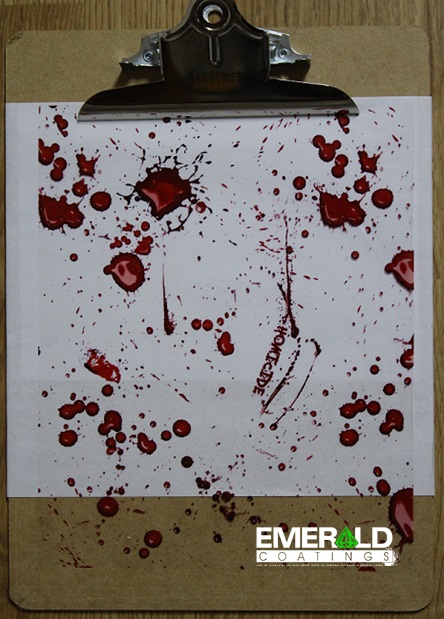

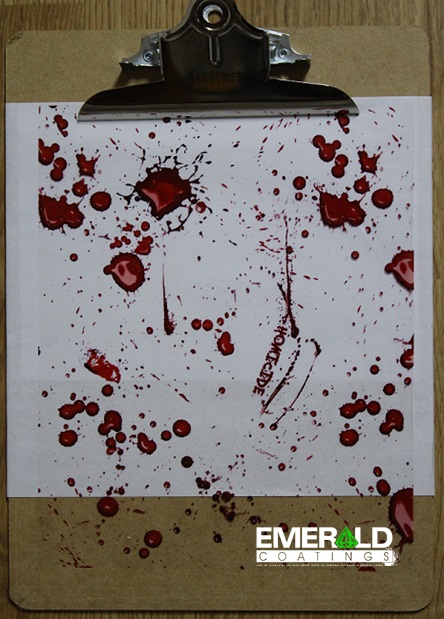

Homicide! Realistic blood splatter ready to be put on any of your items. Homicide has splatters, puddles, and highlights on many parts of the splatters. Homicide looks incredible on so many things and is an awesome one to double dip with – over camo, carbon, skulls… the list goes on and on! White backing on the blood only – the rest of the film is transparent.

1 Meter wide

Recommended Base Color: Any

6” x 1/2” STEEL RULE

• Stainless steel

• Pocket clip

• Graduated in inch and mm

CYLINDER POLISHING SET

1 X 1.5″

1 X 2.25″

1/4” Shank

• For polishing

all metals

• For use with

polishing

compounds

6 pc. Precision

SCREWDRIVER SET

7 pc. Mini

FELT BOB SET

• 1/8” Shank

• Convenient cassette holder

• For polishing metals, plastic, etc.

4 PIECE PICK SET, STAINLESS STEEL