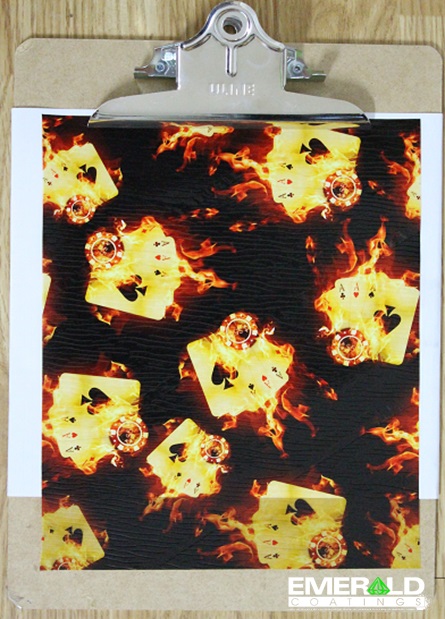

HOT HAND (50 CM WIDE)

Length sold by the Meter

| CHEMISTRY | RED SPLASH | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.5 TO 3.5 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.39 +/- .05 | |||

| THEORETICAL COVERAGE | 56 sq/ft @ 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| MC1099 | VIOLET SPLASH | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.41 +/- .05 | |||

| THEORETICAL COVERAGE | 69 sq/ft @ 2.0 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | n/a | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

TRANSPARENT CANDY RED WITH A BLUE SPARKLE

| MC1100 | CANDY RED DAYBREAK | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F / 20 MIN | |||

| MIN TEMP | 356F / 20 MIN | |||

| MAX TEMP | 400F / 15 MIN | |||

| RECOMMENDED THICKNESS | 2.5-3.5 mils | |||

| PENCIL HARDNESS | F-H | |||

| SPECIFIC GRAVITY | 1.2-1.8 g/cm3 | |||

| THEORETICAL COVERAGE | 51.5 ft2 /lb at 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 20 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| This Product is transparent and will show the base coat through the finish. It is recommended to spray over a metallic silver or chrome powder. This can also be used over polished surfaces with out a base coat. Applying over a polished surface will have the highest shine, however applying over polished or chrome surfaces may be more prone to chipping. Candy / transparent colours are considered tinted clear coats and have the durability and protection of a regular clear coat. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. | ||||

| CHEMISTRY | PINK SPLASH | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.5-4 mils | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.41 +/- .05 | |||

| THEORETICAL COVERAGE | 55 sq/ft @ 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| CHEMISTRY | SASSY RED | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.5 TO 3.5 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.39 +/- .05 | |||

| THEORETICAL COVERAGE | 56 sq/ft @ 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| CHEMISTRY | RED PEARL | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.5 TO 3.5 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.39 +/- .05 | |||

| THEORETICAL COVERAGE | 56 sq/ft @ 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| mc1093 | RED BROWN PEARL | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.50 +/- .05 | |||

| THEORETICAL COVERAGE | 64 sq/ft @ 2 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

*** CLEAR COAT RECOMMENDED FOR EXTERIOR APPLICATIONS AND IMPROVED MAR RESISTANCE ***

| CHEMISTRY | Red Brown Burst | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.50 +/- .05 | |||

| THEORETICAL COVERAGE | 64 sq/ft @ 2 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| MC1092 | Sparkle Red Brown | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.50 +/- .05 | |||

| THEORETICAL COVERAGE | 64 sq/ft @ 2 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| MC1090 | Sparkle Sepia Brown | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.39 +/- .05 | |||

| THEORETICAL COVERAGE | 69 sq/ft @ 2.0 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | n/a | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

| MC1089 | BRIGHT GOLD SEPIA BROWN | |||

| CHEMISTRY | Polyester TGIC Metallic | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.39 +/- .05 | |||

| THEORETICAL COVERAGE | 69 sq/ft @ 2.0 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | n/a | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #9 – Polyester TGIC Metallic | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

BLUE WATER DROPS

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

Available on a 1 meter width roll.

BLACK SPLASH

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

Available on a 1 meter width roll.

5914 Wellington Road 123

Palmerston, ON

T: 1.855.317.4867

Email: andrew@emeraldcoatings.com

Copyright © 2025 by Emerald Coatings | All Rights Reserved