ZEBRA

Black and clear 100 cm wide film

This is a 100cm wide film, all films are sold by the Meter

ZEBRA

Black and clear 100 cm wide film

This is a 100cm wide film, all films are sold by the Meter

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, CLEAR COAT IS NOT NEEDED BUT WILL ADD EXTRA PROTECTION. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ral5001 | 5001 GREEN BLUE | |||

| CHEMISTRY | SD POLYESTER TGIC | |||

| REGULAR CURE TEMP | 375F/10 MIN | |||

| MIN TEMP | 350F/15 MIN | |||

| MAX TEMP | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.43 +/- .05 | |||

| THEORETICAL COVERAGE | 68 sq/ft @ 2.0 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| SDS Sheet info # | #6B – Polyester TGIC (Group B) | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

Hydromonkeys in Canada

Dia De Muertes

Incredibly detailed film with a range of completely awesome day of the dead (Dia De Muertes) inspired images.

Film Width: 100cm

Length sold by the meter

Discontinued

| PC1216 | New Age Silver Hammertone | |||

| CHEMISTRY | POLYESTER TGIC A | |||

| REGULAR CURE TEMP | 375F 13-20 MIN | |||

| MIN TEMP | 356F 15-25 MIN | |||

| MAX TEMP | 400F 10-15 MIN | |||

| RECOMMENDED THICKNESS | 2.5 TO 3.5 MILS | |||

| PENCIL HARDNESS | 2-H | |||

| SPECIFIC GRAVITY | 1.2-1.8 g/cm10 | |||

| THEORETICAL COVERAGE | 51.5 ft2 /lb at 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | NA | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 80 in/lb | |||

| SDS Sheet info # | #6A – Polyester TGIC (Group A) | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. USE ZINC RICH PRIMER OVER STEEL PARTS FOR EXTERIOR APPLICATIONS | ||||

| PC1217 | New Age Black Hammertone | |||

| CHEMISTRY | POLYESTER TGIC A | |||

| REGULAR CURE TEMP | 375F 13-20 MIN | |||

| MIN TEMP | 356F 15-25 MIN | |||

| MAX TEMP | 400F 10-15 MIN | |||

| RECOMMENDED THICKNESS | 2.5 TO 3.5 MILS | |||

| PENCIL HARDNESS | 2-H | |||

| SPECIFIC GRAVITY | 1.2-1.8 g/cm10 | |||

| THEORETICAL COVERAGE | 51.5 ft2 /lb at 2.5 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | NA | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 80 in/lb | |||

| SDS Sheet info # | #6A – Polyester TGIC (Group A) | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. USE ZINC RICH PRIMER OVER STEEL PARTS FOR EXTERIOR APPLICATIONS | ||||

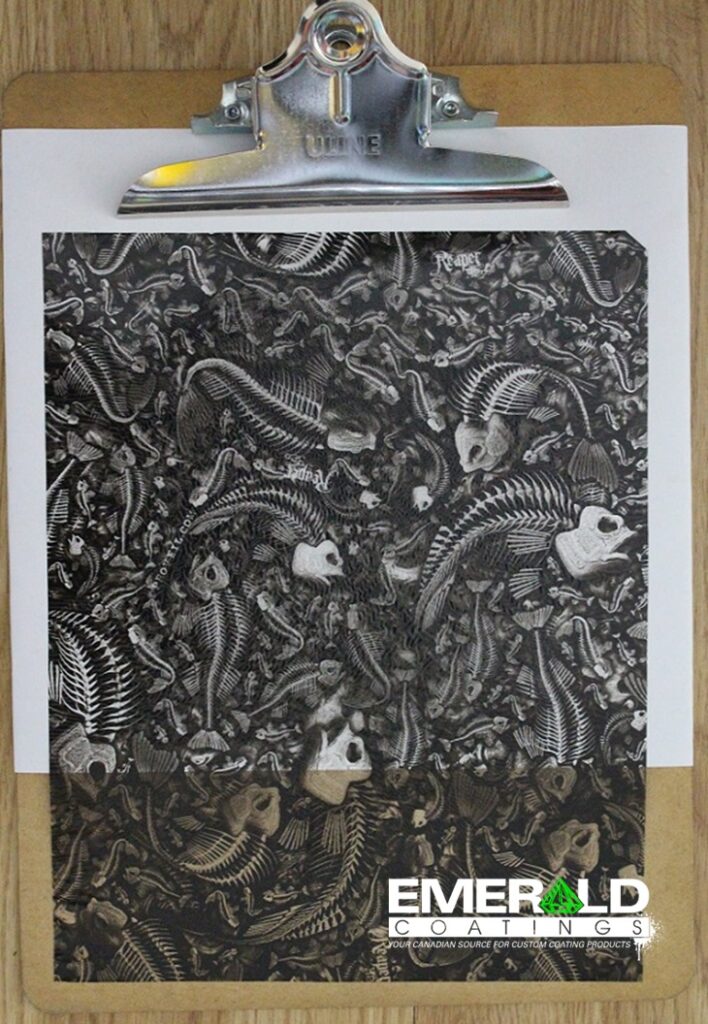

PROVEIL REAPER Z

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

Available on a 1 meter width roll.

PROVEIL REAPER H20

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

Available on a 1 meter width roll.

PROVEIL REAPER XL H20

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

One color film featuring metallic Reaper fish printed upon clear backing allowing your elected base color to enhance/accent this design. Largest fish in design measures 2.5″ in length. Smallest fish measures 1″ in length.

Available on a 1 meter width roll.

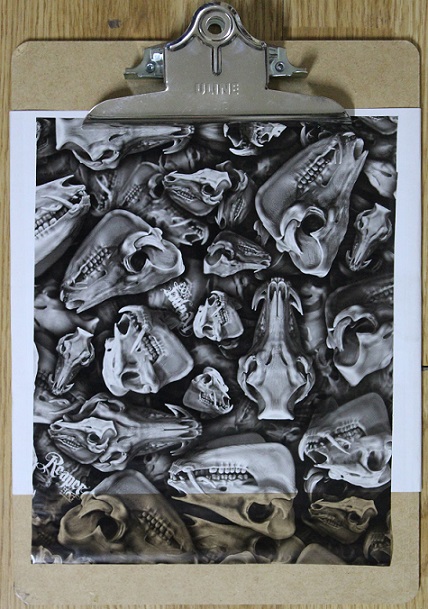

PROVEIL REAPER HOG

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

PROVEIL REAPER BUCK

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

Available on a 1 meter width roll.

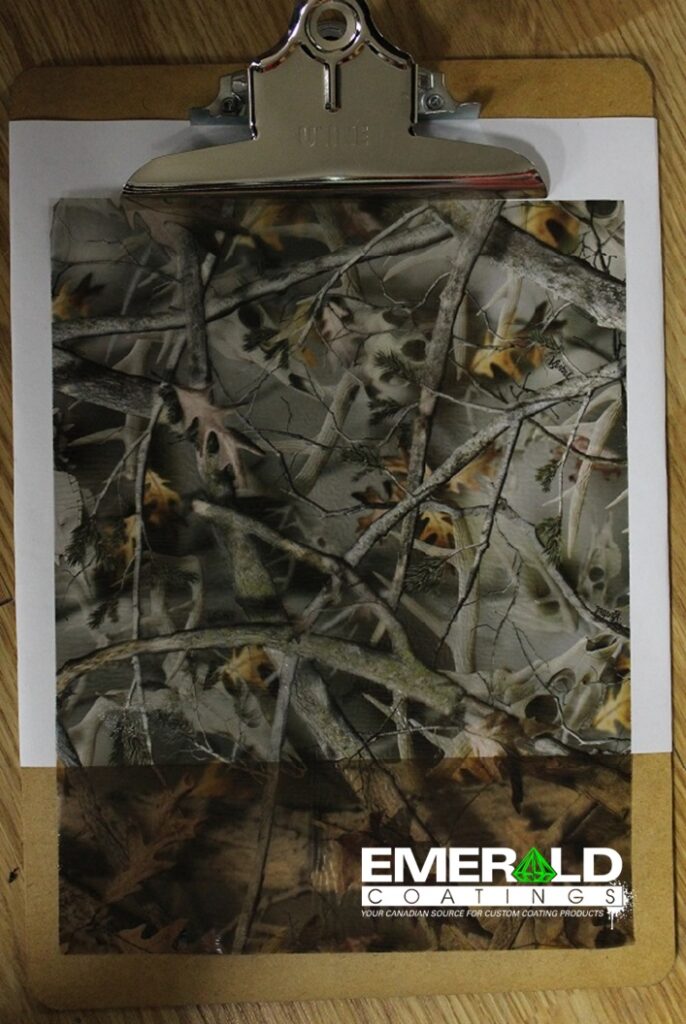

PROVEIL REAPER BLACK

THIS IS A PREMIUM PVA FILM PRINTED ON THICK 35 MICRON FILM.

Available on a 1 meter width roll.

Cerakote MC-160 Ceramic Clear is the strongest clear coat on the market. MC-160 is our most popular clear coat because of its industry leading hardness, chemical resistance, wear performance and UV stability. MC-160 is a high gloss, air cured, ceramic clear coating that can be used as a top coat over a number of materials such as:

-All metal types including polished metals

-Paints

-Composites & Fiberglass

-Plastics

-Hydrographics

-PVD

-Thermal Stability to 300F

In addition to performance, MC-160 is designed for ease of application, is VOC-exempt and can be sprayed in all 50 states. Visit the product testing page for extensive ASTM test results and see why Cerakote is the World’s Strongest Clear Coat.

Cure Schedule (Ambient Temperature):

Tack free at 35-45 minutes

Dry after 24-hours

100% cure after 5days

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

| RAL5008 | RAL 5008 GREY BLUE | |||

| CHEMISTRY | SD POLYESTER TGIC | |||

| REGULAR CURE SCHEDULE | 375F/10 MIN | |||

| MIN RANGE | 350F/15 MIN | |||

| MAX RANGE | 400F/7 MIN | |||

| RECOMMENDED THICKNESS | 2.0 TO 3.0 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.43 +/- .05 | |||

| THEORETICAL COVERAGE | 68 sq/ft @ 2.0 mils | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 80-95+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 120 in/lb | |||

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS, CLEAR COAT IS NOT NEEDED BUT WILL ADD EXTRA PROTECTION. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. | ||||