| Convenient – Easy to do in house. No waiting for heatup of blackening solution. No waiting for the unpredictable return of parts from an outside vendor. Eliminates high outside vendor costs. Retain control of production and quality. Ideal for high volume or short runs. Works especially well for blackening large volume of small parts in a rotating barrel.

Higher Productivity – Parts can be blackened in two minutes vs 15 to 30 minutes for hot oxide. Normally twice the amount of parts can be blackened in the same amount of time as with hot oxide.

Controllable – Long bath life, blackening solution may be replenished indefinitely with periodic additions of fresh concentrate.

Versatility – Blackens cast iron, forged steels, mild steels, hardened tool steels and powdered metal parts. No white salt bleedout as is common with hot oxide.

Dimensional Control – No heat distortion. No smutty rub-off as with other room-temperature blackening processes.

Energy Cost Saving – Blackening is done at room temperature vs hot oxide blackening done at 290°F.

Safety – Blackening solution uses odorless, mild water-dilutable chemicals that require no venting vs hot oxide. No hazardous caustic chemicals with fumes that present health hazards and no spattering of hot, skin-burning chemicals.

Low Maintenance – Longer Equipment Life – No expensive pollution control equipment.

Parts Coverage – 600 to 1200 sq. ft. of surface area blackened per gallon of concentrate.

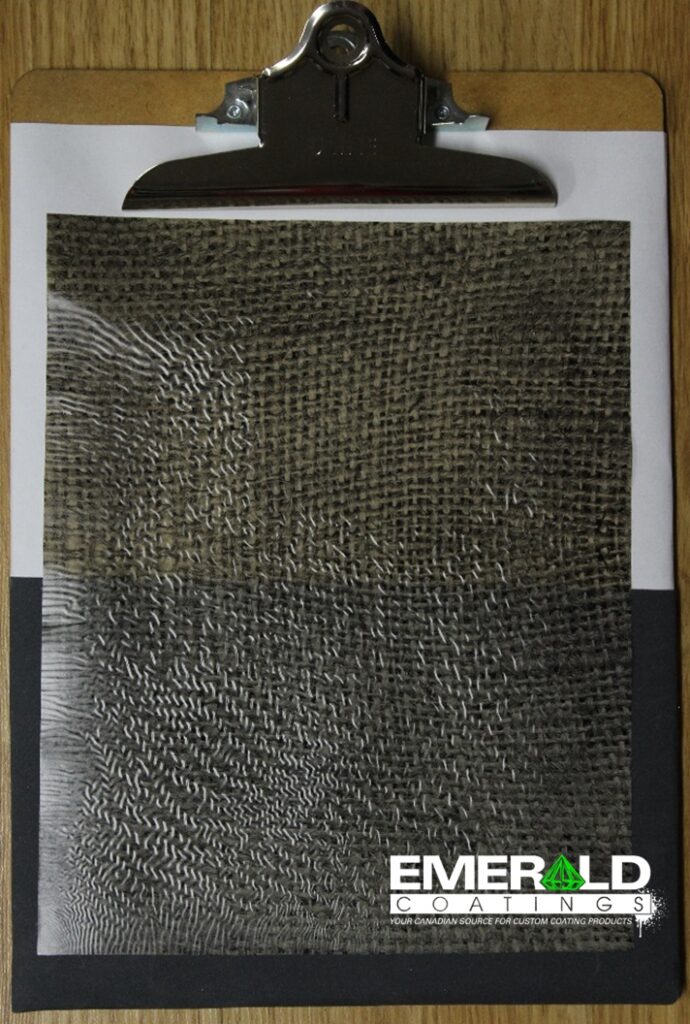

How to achieve professional results in minutes:- Thoroughly clean the part to be blackened by either sandblasting, wire brushing, wire wool abrasive cleaning, or by scrubbing in ‘VIM’ or ‘COMET’ household abrasive cleaner. Make sure you have removed all rust, paint, oil and grease. SP Cleaner/Degreaser can also be used.

Immerse the part in the mixed Black Oxide Solution and swirl around for between 30 seconds and 5 minutes. Alternatively, the part may simply be placed in the solution for 5 – 10 minutes. Remove the part from the solution and rinse in fresh water.

Immediately brush on or dip into the Penetrating Sealant, and allow to soak in the liquid for 5-10 minutes. Shake off any excess and allow to dry thoroughly before handling. Penetrating Sealer imparts a slightly oily feeling to the parts. If a non-oily finish is desired, do not use the Penetrating Sealer after blackening, and instead use Caswell Sealer.

Some hardened or specialized steels will not readily accept the blackening process. Activation can be done using a 10% sulfuric acid and distilled water etch 2 to 5 minutes, then thoroughly rinse before immersing into the black oxide. To enhance blackening effect warm the part to approx. 120 deg F, or warm the liquid to 80 deg F before use.

Some hardened and specialized steel alloys may blacken to a deeper black finish when activated using our Black Oxide Activator.

BLACK OXIDE INSTRUCTIONS

Black Oxide works on steel or iron parts only and will not blacken Stainless Steel.

Make a small test batch first to ensure the 9:1 dilution will work with your process, some parts may require a stronger mixture i.e. 4:1 or 2:1. Brush on or spray method may also require a stronger mixture.

Black oxide is not a high corrosion resistant coating. The corrosion resistance comes from the top coat, which can be one of the following, penetrating oil, sealer concentrate, wax or clear coat can all be used. It is not suitable for severe outdoor applications or corrosive environments.

|