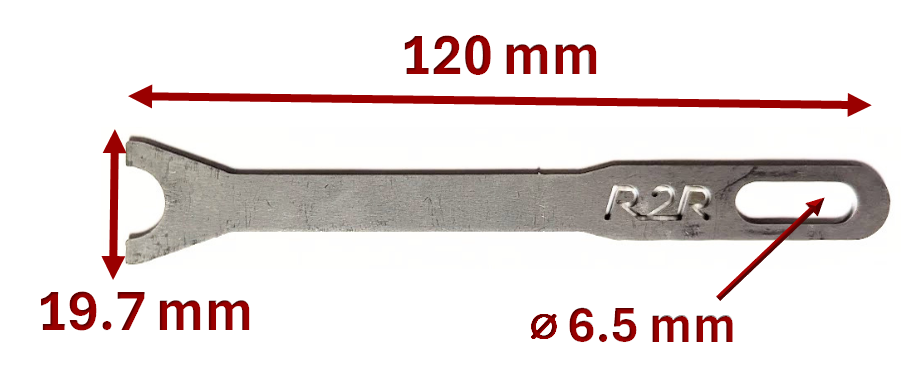

Axis Anchor (Mini) – Pair

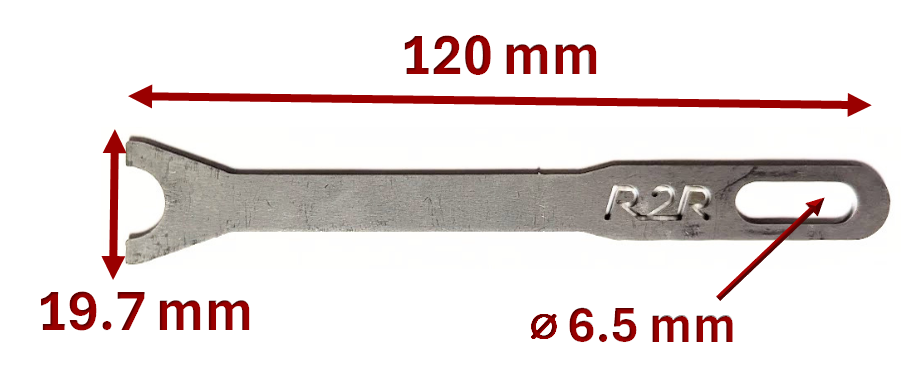

The Axis Anchor Mini is engineered for smaller valve stem openings, making it the go-to solution for Harley-Davidson wheels, bike rims, and other lightweight parts that require secure hanging during powder coating or painting.

Sold as a pair

Key Specs:

-

Fits valve stem holes up to 3/8″ diameter

-

Constructed from 304 stainless steel

-

0.06″ thickness

-

5.97″ overall length

-

Load rated for parts up to 75 lbs

Compact but strong, this mini version delivers dependable performance for smaller-scale jobs where precision and fit matter most.

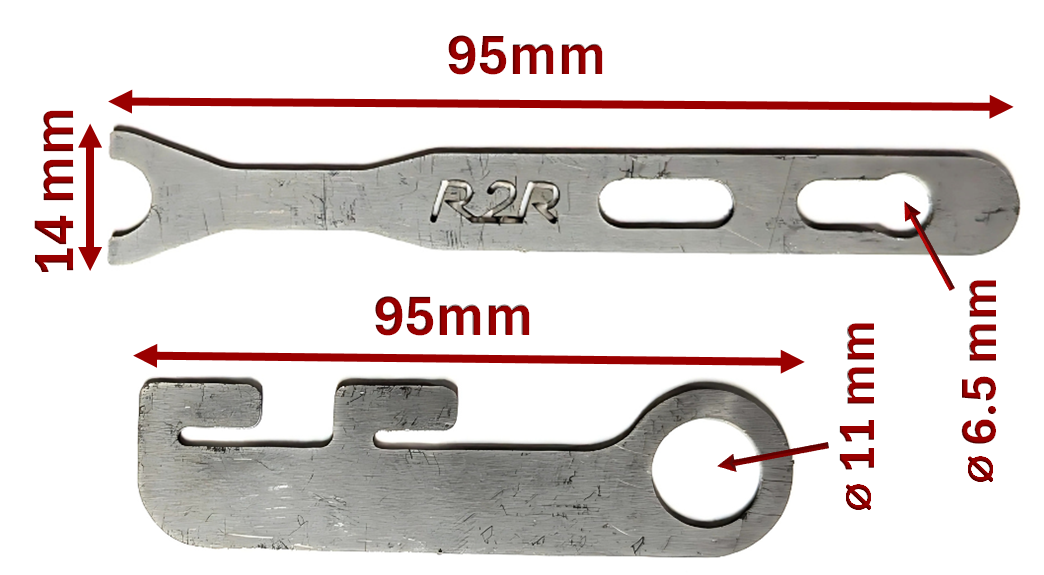

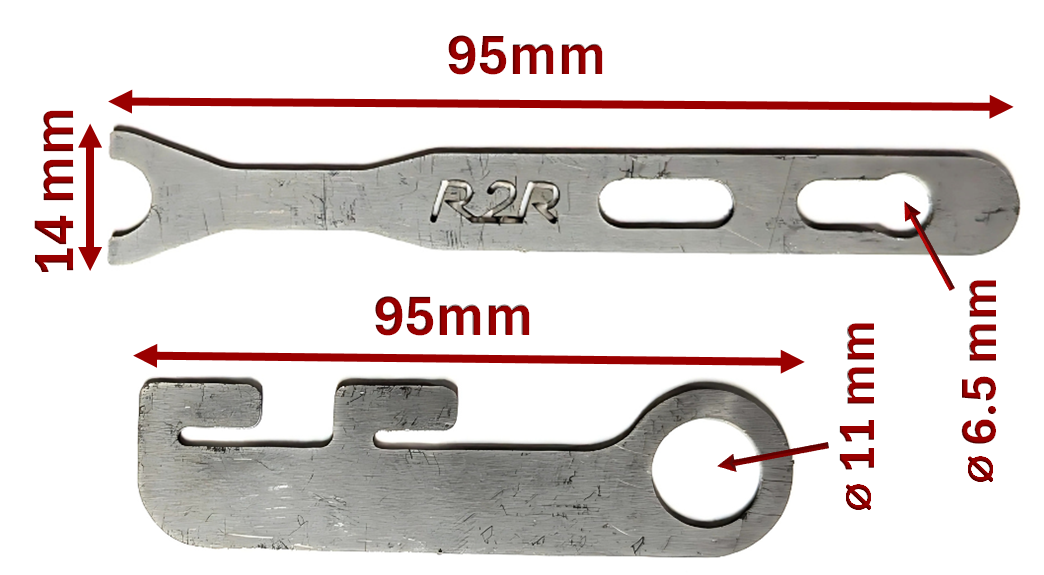

Axis Anchor – Set of 4

The Axis Anchor is a two-piece hanging solution designed to securely support wheels and other heavy items during powder coating or painting.

Each set includes, 4 Axis Anchor hooks, 4 Axis Anchor latch adaptors

Key features:

-

Compatible with standard valve stem holes up to ½” in diameter

-

Made from durable 304 stainless steel

-

0.06″ thick

-

Measures 3.74″ in total length

The Axis Anchor HD series is designed to hold extra heavy wheels and work pieces.

- Sold in quantity of 4

- Designed to work with larger valve stem holes up to 3/4″ diameter.

- 304 stainless steel construction

- Thickness: 0.074″

- Overall Length: 4.75″

R2R Axis Anchor Master Deluxe Kit

This all-in-one kit brings together the full range of R2R Axis Anchors into one streamlined package. Perfect for serious users who want the complete setup, the kit includes:

-

1x Original R2R Axis Anchor Set

-

2x Mini R2R Axis Anchor Sets

-

1x Heavy Duty R2R Axis Anchor Set

Cerakote Burnt Bronze is a medium bronze with gold metallic. *NOTE: This product does not require catalyst. This color does require a 100 Mesh Strainer . Cerakote Burnt Bronze C Series Ceramic Coatings will perform at temperatures up to 1700°F and set the industry standard in high temperature coatings. C Series coatings are a line of air cured, ready to spray ceramic coatings. Check out the application guides, technical data sheets and SDS information.

-Cure Schedule Air Cure: Tack Free 45- 60 minutes, Full Cure 5

Days

-Recommended Thickness (mil) 1

-Gloss Level / Units (GU) Matte /

-Coating Stability (°F) Max. Temp. 1700°

-Color Stability (°F) Max. Temp. 500°

*** SHAKE WELL BEFORE USE ***

***PLEASE STORE IN ROOM TEMP AND VENTILATE CONTAINER WEEKLY***

Nanner Peel Chemical Stripper

Nanner Peel is a powerful water-based paint and powder coating remover that is non-toxic, biodegradable, and environmentally safe. It’s specially formulated for use on aluminum and other non-ferrous metals, making it ideal for job shops, coaters, and restoration work.

This stripper can be used at full strength or diluted up to 50% with water. For best results, heat the solution to 165–175°F in a stainless-steel drum with a lid. Avoid using mild steel tanks, and always keep the lid on when not in use to minimize evaporation.

Directions for Use:

- Prepare a strip tank with proper ventilation and a secure lid.

- Submerge parts in solution (diluted or full strength).

- Recommended dwell time: 20 minutes at 165–175°F. Dwell time may vary based on coating.

- Rinse parts thoroughly using fresh water and a pressure washer.

Key Features:

- Designed for use on aluminum and non-ferrous metals

- Also effective on many ferrous metals

- No methylene chloride – safer for users and the environment

- Low vapor pressure means fewer VOCs

- Can remove paints, epoxies, and various powder coat types

- Safe for most alloys except magnesium

⚠️ Caution – Magnesium Warning:

Do not use Nanner Peel on magnesium or on parts that may contain magnesium alloys. Some aluminum parts—especially castings—may contain magnesium. If you’re unsure, do not leave parts in overnight. Extended dwell times on magnesium-containing alloys can cause pitting or surface damage. Always test on a small area first when working with unknown aluminum types.

This chemical is produced by Cherokee Chemical Co.

OUR NEW POLYURETHANE CRYSTAL CLEAR

This is a High gloss clear with great clarity and quality that resists yellowing, ideal for whites and light silvers. Smooth application, but it’s more expensive than other clears.

| PC1180 |

PC1180 |

| CHEMISTRY |

POLYURETHANE GROUP A |

| REGULAR CURE TEMP |

400F/15 min |

| MIN TEMP |

NA |

| MAX TEMP |

NA |

| RECOMMENDED THICKNESS |

2.0-3.0 mils |

| PENCIL HARDNESS |

2H |

| SPECIFIC GRAVITY |

1.19 +/-0.05 g/cm³ |

| THEORETICAL COVERAGE |

162 sq.ft/lb/mil |

| PENCIL HARDNESS |

2H minimum |

| GLOSS LEVEL (60°) |

95 |

| SALT SPRAY |

1000 |

| BALL IMPACT |

40 |

| SDS Sheet info # |

#5A – Polyurethanes (Group A) |

| SDS link |

https://emeraldcoatings.com/sds-sheets/ |

| WEATHER RESISTANT POWDER COATING FOR INTERIOR AND EXTERIOR APPLICATIONS. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible Delamination between coatings. |

White Glass Cloth Tape High Temperature tape. Good for 500F.

Highly resistant to abrasives and flame retardant. Great for high-heat applications and sandblasting.

High temp tape is pressure sensitive, you must apply pressure to the tape after it has been applied to the sub-straight.

- Length: 36 YDS long

- Tape Type: Glass Cloth

- Colour: White

- Maximum Temperature: 500°F

- Total Thickness: 7 mils

- Adhesive Thickness: 2 mils

- Backing Thickness: 5 mils

- Dielectric Strength (v/mil): 3000

- Adhesion Strength (oz/inch) 40

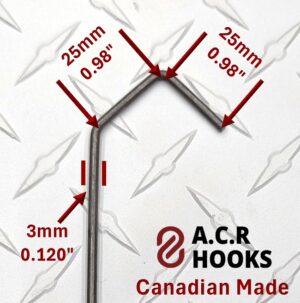

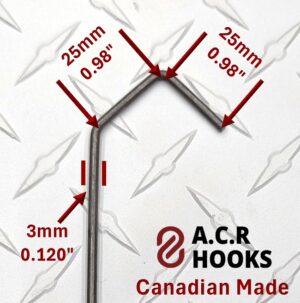

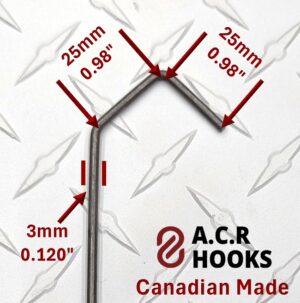

3mm 10″ V Coating Hook, (30 lbs weight load). Used for Powder coating and other paint applications. Perfect for High heat applications. Our 3mm 10″ V Coating Hook are made with Hardened spring steel.

| Name |

10″ V Hook, 0.12″ Thick |

| Part# |

HVM10 |

| Hook Style |

V Hook |

| Thickness |

0.12″ (3mm) |

| Total Length |

10″ (254mm) |

| Hooks Per bag |

50 pack or 1000 pack |

| Estimated Load capacity |

30 lbs |

All our High heat powder coating hooks are made in Canada by ACR Hooks. For more hook options, or custom size hooks, checkout their website WWW.ACRHOOKS.COM

Need a Heavy duty powder coating hook? Check out our 4.5mm Hooks Meant to hold heavier work pieces.

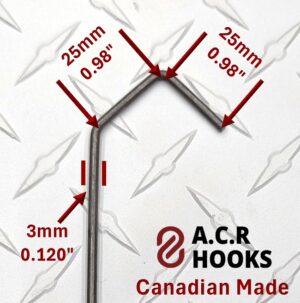

3mm 8″ V Coating Hook, (30 lbs weight load). Used for Powder coating and other paint applications. Perfect for High heat applications. Our 3mm 8″ V Coating Hook are made with Hardened spring steel.

| Name |

8″ V Hook, 0.12″ Thick |

| Part# |

HVM8 |

| Hook Style |

V Hook |

| Thickness |

0.12″ (3mm) |

| Total Length |

8″ (152.4mm) |

| Hooks Per bag |

25 pack or 1000 pack |

| Estimated Load capacity |

30 lbs |

All our High heat powder coating hooks are made in Canada by ACR Hooks. For more hook options, or custom size hooks, checkout their website WWW.ACRHOOKS.COM

Need a Heavy duty powder coating hook? Check out our 4.5mm Hooks Meant to hold heavier work pieces.

3mm 6″ V Coating Hook, (30 lbs weight load). Used for Powder coating and other paint applications. Perfect for High heat applications. Our 3mm 6″ V Coating Hook are made with Hardener spring steel.

| Name |

6″ V Hook, 0.12″ Thick |

| Part# |

HVM6 |

| Hook Style |

V Hook |

| Thickness |

0.12″ (3mm) |

| Total Length |

6″ (152.4mm) |

| Hooks Per bag |

1000 |

| Estimated Load capacity |

30 lbs |

All our High heat powder coating hooks are made in Canada by ACR Hooks. For more hook options, or custom size hooks, checkout their website WWW.ACRHOOKS.COM

Need a Heavy duty powder coating hook? Check out our 4.5mm Hooks Meant to hold heavier work pieces.

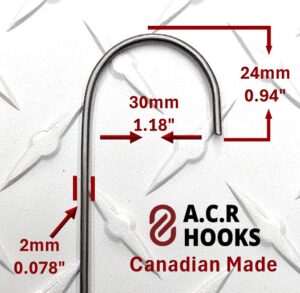

3mm 8″ S Coating Hook, (30 lbs weight load). Used for Powder coating and other paint applications. Perfect for High heat applications. Our 3mm 8″ S Coating Hook are made with Hardener spring steel.

| Name |

8″ S Hook, 0.12″ Thick |

| Part# |

HSM8 |

| Hook Style |

S Hook |

| Thickness |

0.12″ (3mm) |

| Total Length |

8″ (203.2mm) |

| Hooks Per bag |

50 pack or 1000 pack |

| Estimated Load capacity |

30 lbs |

All our High heat powder coating hooks are made in Canada by ACR Hooks. For more hook options, or custom size hooks, checkout their website WWW.ACRHOOKS.COM

Need a Heavy duty powder coating hook? Check out our 4.5mm Hooks Meant to hold heavier work pieces.