$28.25

Discount Pricing

Description

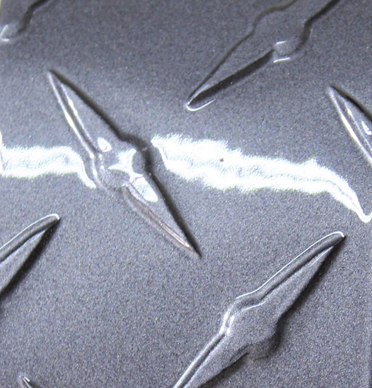

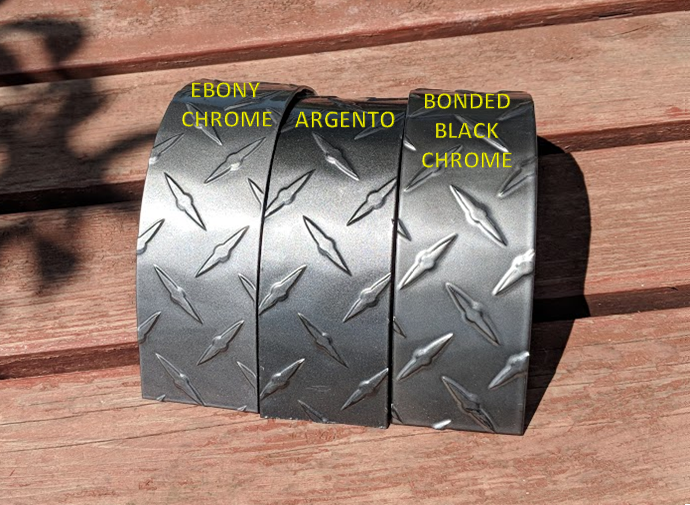

EBONY CHROME

THIS PRODUCT IS ANOTHER ADDITION TO OUR BLACK/SMOKE CHROMES

| PC1059 | EBONY CHROME | |||

| CHEMISTRY | POLYESTER TGIC A | |||

| REGULAR CURE TEMP | 400F/10 min | |||

| MIN TEMP | NA | |||

| MAX TEMP | NA | |||

| RECOMMENDED THICKNESS | 2.0-3.0 mils | |||

| PENCIL HARDNESS | 2-H | |||

| SPECIFIC GRAVITY | 1.24 +/- .05 | |||

| THEORETICAL COVERAGE | 155ft^2 /lb/mil | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 85+ | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 160 in/lb | |||

| SDS Sheet info # | #6A – Polyester TGIC (Group A) | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| *Clear Coat Recommended, will Improved Mar Resistance and will improve the over all look and depth of the metallic finish. *When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. Over curing the base coat can cause possible delamination between coatings. | ||||

Additional information

| Weight | 1 lbs |

|---|---|

| Dimensions | 2.37 × 2.37 × 2.37 in |