$17.35

Discount Pricing

SKU: PC1108

Categories: Bronze, Brown, METALLIC COLOURS, Powder Coating, Powder Coating Powders, SATIN METALLIC'S

Tags: bronze, brown, Copper / Bronze, Powder Coating

Description

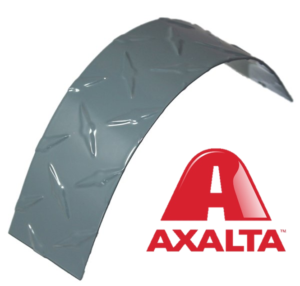

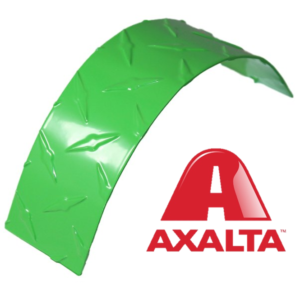

| PC1108 | MAPLE PENNY METALLIC | |||

| CHEMISTRY | POLYURETHANE GROUP A | |||

| REGULAR CURE TEMP | 375F/15 min | |||

| MIN TEMP | NA | |||

| MAX TEMP | NA | |||

| RECOMMENDED THICKNESS | 1.50 – 3.50 MILS | |||

| PENCIL HARDNESS | 2H | |||

| SPECIFIC GRAVITY | 1.47± 0.03 | |||

| THEORETICAL COVERAGE | NA | |||

| PENCIL HARDNESS | 2H minimum | |||

| GLOSS LEVEL (60°) | 20 | |||

| SALT SPRAY | 1,000 hours | |||

| BALL IMPACT | 80 in/lb | |||

| SDS Sheet info # | #5A – Polyurethanes (Group A) | |||

| SDS link | https://emeraldcoatings.com/sds-sheets/ | |||

| No top coat will leave you with a unique satin metallic finish. Add a high gloss clear to make the metallic’s pop and turn this into a whole different colour. Add a flat clear to keep the satin look while adding extra protection to the part. This product is exterior durable however, parts subject to more extreme conditions like car rims should be clear coated. When coating in 2-3 stages, always particularly cure the base coat around 50-75% of the recommended cure schedule to allow the top coat to properly cross-link with the base coat. This method of curing will result in the best possible bond between coats. over curing the base coat can cause possible De-lamination between coatings. | ||||

Additional information

| Weight | 1 lbs |

|---|---|

| Dimensions | 2.37 × 2.37 × 2.37 in |